Our services

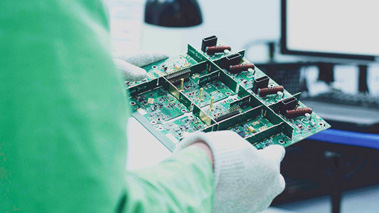

Contract

Manufacturing

Sourcing and Supply Chain Management - SCM

We provide material management for the duration of a product’s life cycle: from solution design, through optimization in cost reduction. We also ensure obsolescence management and material availability management.

Engeenering Services

& Product Management

Our independent teams of engineers deal with product life cycle management: from design to manufacture and assembly stage, through alternative materials, and finally - time management to product end-of-life.

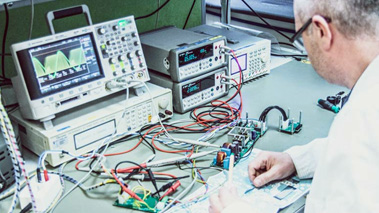

Test & Test

Development

We have comprehensive in executing electrical, optical, burning, spurs and distortion, and environmental stress tests. Upon request, we can design any test environment to examine whether the product works the way it should.

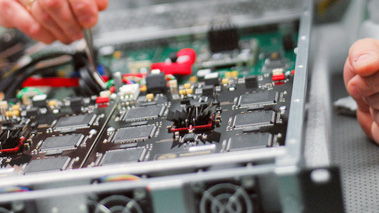

Design

Services

We have experience in mechanics, electronics and software design. In our design process we use state-of-the-art design tools and methodologies to maintain the quality of our design services on the highest level.

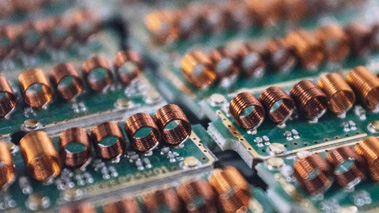

Prototyping

Our prototyping capabilities include: Printed Circuit Board Assemblies (PCBA), 3D Printing, mechanical rapid prototyping, assembly and tests.

NPI - New Product

Introduction

Among other things, in our New Product Introduction process we rely on DFMA - Design for Manufacturing and Assembly methodology, FMEA - Failure Mode Effect Analysis and DFT - Design for Testability Analysis.

Product

Certification

We offer global certification, qualification & regulatory services. We can perform in-house preliminary and external tests, and approval in globally recognized laboratories.

In case you

need further

help...

If you cannot find any solution on the service list, please fill in the contact form. VECTOR BLUE HUB technical experts team is willing to take up the challenge.

Watch the short video about

our design and electronics manufacturing services!

Customers

In our portfolio, you will find electronics for startups, niche companies and global market leaders from the telecommunications, media, entertainment, IoT and energy industries.

We have completed over 500 projects for customers in Europe and America. More than 5 million people around the world use various different services owing to electronics solutions and devices designed or manufactured by VECTOR BLUE HUB.