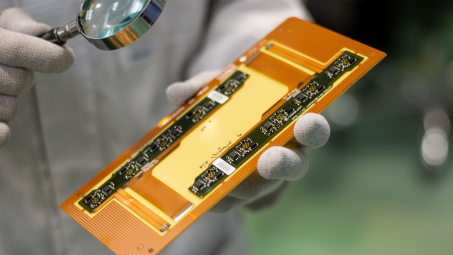

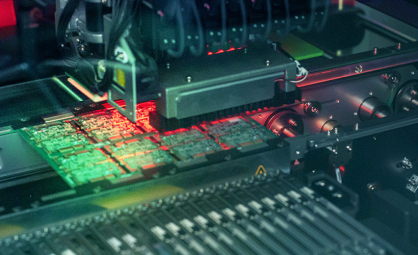

Producing and assembling printed circuit boards (PCBs) and other electronic components demands an environment meticulously safeguarded against electrostatic discharges (ESD). ESD, an invisible yet pervasive threat, can compromise the integrity of sensitive electronic components, leading to product failures and financial losses. Ensuring the manufacturing process is ESD-safe is paramount to maintaining product quality and reliability.

The COVID-19 pandemic accentuated the fragility of the global supply chain, forcing businesses worldwide to confront the urgent need for greater resilience in their operations. Despite awareness of the risks posed by natural disasters and geopolitical events, the pandemic emphasized the critical need for a more adaptive approach to supply chain management. The reality is that supply chain disruptions are inevitable and can arise from various unforeseen events. To navigate these challenges, companies must embrace the adaptive supply chain, utilizing advanced cloud-based technologies to ensure preparedness for any scenario.

Choosing the suitable PCB assembly manufacturer is not easy - it's like finding the perfect recipe for your favourite dish. You want all the right ingredients, precise measurements, and a dash of expertise to ensure the end result is not just good but exceptional. Much like cooking, assembling a PCB requires a blend of precision, technology, and reliability. And just as every cook has their own style, every PCB assembly company has unique strengths, specialities, and production capabilities.

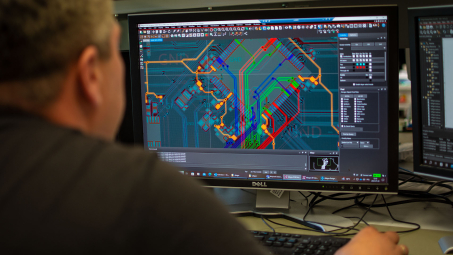

Bringing together design and manufacturing under one roof marks a big leap forward in turning ideas into real products. This smart move does more than just save time; it drives innovation, making it faster and easier to bring new, high-quality products to market.

In an era dominated by technology, where sustainability and efficiency are paramount, battery condition management via a battery management system (BMS) is becoming an extremely important component. Why is this the case? These systems, complex in their functionality, are a lifeline for extending the utility and reliability of battery packs in a wide range of applications. From electric vehicles (EVs) to portable electronics and large-scale energy storage systems, the role of the BMS is extremely important.

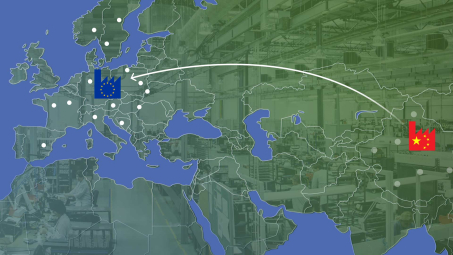

For many years, the electronics manufacturing industry was dominated by the appeal of low-cost offshore production, especially in China. Companies sought to maximize profits by leveraging the cost advantages offered by these regions. However, the tide is turning. A growing number of companies are reevaluating their offshore strategies and bringing their production processes back to Europe – a trend known as "reshoring."

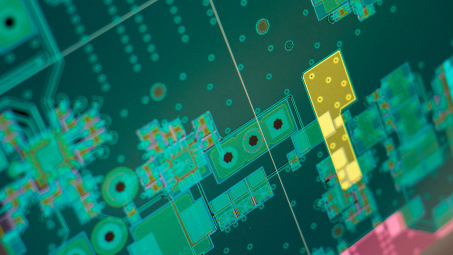

Designing electronic circuits involves a combination of creativity and accuracy. It's fairly obvious that if you want to be successful at electronic circuit design, you must understand each component and practice a lot. However, there are several guidelines that designers and DIY beginners must follow to create circuits that are both optimal and efficient.

In the intricate world of Electronic Manufacturing Services (EMS), mastering the art of cost management and ensuring supply chain transparency are not just strategic advantages—they're necessities. A robust cost management plan becomes the backbone of successful project management, particularly when it comes to navigating the complexities of project costs and the supply chain. Effective cost management strategies are essential for project managers and project teams alike, as they seek to balance the demands of quality, efficiency, and budgetary constraints.

As a VECTOR BLUE HUB, we are pleased to announce our latest achievement: obtaining ISO environmental certification. This not only signifies our dedication to sustainable practices but also elevates our standing in the competitive landscape of electronics design and manufacturing. By securing the ISO 14001 certification, we demonstrate our commitment to eco-innovation and the adherence to global environmental standards.

In the dynamic world of Electronics Manufacturing Services (EMS), the intricate dance between a business and its EMS partner is pivotal. This partnership, often underestimated, can significantly influence a business’s trajectory. The internal processes and procedures of an EMS partner are not mere back-office mechanics; they are the gears that drive the industrialization of your product. This article provides significant insight into the impact these processes have on your business and how you can leverage this understanding to foster more effective collaboration and improve internal processes.

When it comes to creating electronics, it's a complex world with numerous processes to navigate. As a product owner aiming to launch your innovations, you have two options: either manage every aspect of the development process yourself, provided you possess the expertise and resources or hire an external electronic design company. However, for most business owners looking to make a smart choice, the strategic approach often involves capitalizing on your strengths while delegating tasks where your expertise may be limited.

The business landscape in the Electronics Manufacturing Services (EMS) industry is a complex labyrinth of evolving technologies, rapidly changing consumer demands, and stiff competition. In this dynamic scenario, a key factor that determines the success of a venture is the effectiveness of its business model. But how can one ensure the viability and scalability of a business model, especially in an industry as intricate and competitive as EMS? Read this article to find out!

In electronics manufacturing, envisioning the process as a well-orchestrated symphony could be a compelling perspective. In this symphony of creation, each participant plays a vital role: engineers, various vendors, and an array of components come together, much like musicians in an orchestra, to harmonize their expertise and resources.

In today's dynamic technological landscape, devices have seamlessly woven themselves into the fabric of our daily lives, from urban comforts to the challenging fringes of our world. As society advances in search of new solutions for growing needs, there is also an increasing demand for resiliently designed, intelligent equipment in the telecommunications sector, across various fields of its application. As we push through this technological era, the hardening and reliability of these devices in harsh conditions become paramount.

Printed Circuit Board (PCB) connectors are important components in electronic devices such as sensors, microcontrollers, and peripherals, to the PCB, enabling the transmission of electrical signals and power between different components. They come in a wide variety of types, each designed for specific applications and performance requirements. A broad range of PCB connection types are available to meet various applications, conditions, circuit types, and design needs.

In the world of electronics, where technological advancements occur rapidly, the multilayer PCB has established its dominance. Over the past few decades, multilayer printed circuit boards have become an indispensable part of modern electronic devices, enabling them to meet the complex needs of today's consumers.

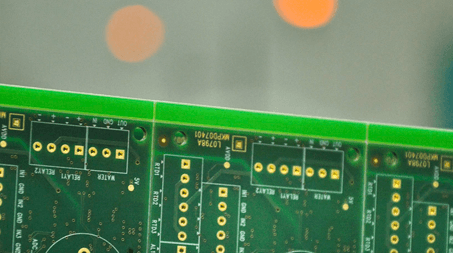

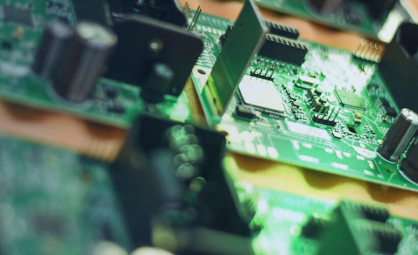

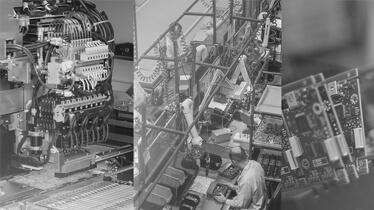

Manufacturing electronic components and devices is a very intricate process. Take phones, for example: From the screen to the frame and communication devices, each component is extremely intricate and has seen decades of research go into it. One component, however, stands above the rest and acts as the heart of most electronic devices, and that's the printed circuit board (PCB). From smartphones and laptops to household appliances, without the PCB, none of these devices function at all.

Creating an electronic circuit project typically involves the production of a printed circuit board (PCB). There are many different PCB types available on the market today. However, the single-layer PCB holds a special place among the various types of printed circuit boards available. If you've ever wondered what single-layer PCBs are, how they work, and when they're the ideal choice for your projects, you've come to the right place.

Modern electronics, where smaller sizes and increased capabilities are in demand, stimulated the development of Surface-Mount Technology (SMT). However, as demand grew, there was a requirement for faster assembly and higher-density technologies to accommodate these items.

It is no secret that printed circuit boards are the backbone of electronic devices. You will most find them in everyday electronics from smartphones and household appliances. They house essential electronic components and allow various parts of the device to communicate, which is required for these devices to properly function. Though they underpin much of our modern lifestyle, many people don't consider the technology that makes them function!

Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two common types of technology used with printed circuit boards (PCBs). Professionals in the industry must understand the distinctions and benefits of these components. This article provides a comprehensive overview of Surface Mount Device (SMD) and THT components, highlighting their shared characteristics, differences, and the advantages of using electronic components in PCBs.

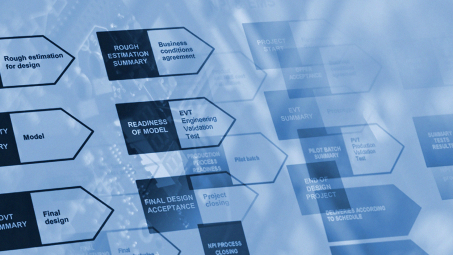

The new product introduction process always carries many potential risks. A successful concept phase preceding the development stage is crucial because implementing changes with the design process underway can be expensive and time-consuming.

The soldering process is an integral part of electronic assembly. When designing and manufacturing consumer electronics, all the electrical components of the printed circuit boards must be assembled onto it, and this is where soldering comes into play.

Surface Mount Technology (SMT) is a vital process that is transforming the electronics industry. In this article, we delve into the intricacies of SMT assembly, exploring its advantages over through-hole technology, the applications in which it is used, and the process involved in its implementation.

The electronics industry is a vague idea that covers everything from simple sensor modules in the IoT sector to complex telecommunication equipment. Each industry has its own requirements and certification restrictions, which means responsible and business-aware Electronic Manufacturing Service (EMS) partners know their strengths.

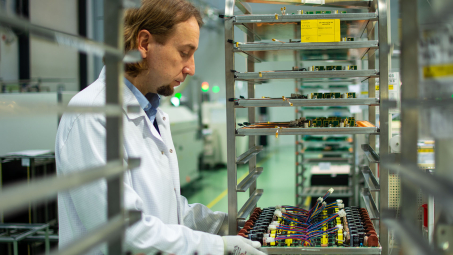

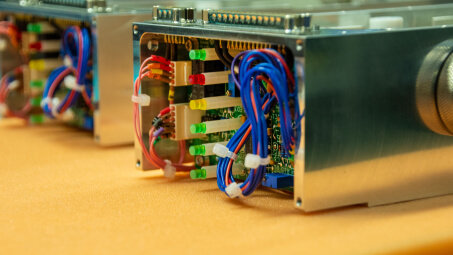

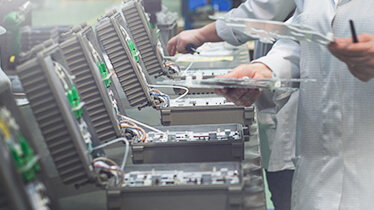

When it comes to electronic manufacturing services, then integrated, fully functional products are our ultimate goal. This is why the final assembly and box-build capabilities complement our contract manufacturing services.

The complexity in electronic hardware design has become a burden for any company looking to accelerate the time to market new products. This is especially true in the technology industry, where new products and innovations are constantly being developed.

The electronics manufacturing process is challenging and sometimes very demanding. Due to unforeseen difficulties and product complexity, most hardware startups fail before their first innovative product hits the market. Thankfully, newer technologies, design techniques, and procedures have decreased the risk of failure in electronic device development, resulting in more successful products.

Electronic products have revolutionised how we live, work, and interact with the world around us, playing an increasingly vital role in nearly every aspect of modern society. As technology continues to rapidly evolve, however, it’s becoming increasingly clear that many of these products will need to be redesigned to stay relevant and competitive.

Have you ever wondered how many electromechanical products there are around us? Electric lights brighten our homes, flat-screen televisions entertain us, while power supplies and accessories transmit power to every electronic product we use. Get a glimpse into what it takes to create them, and how we can help you!

Every functioning electronic device is powered by a core—the printed circuit board (PCB). Printed Circuit Boards (PCBs) are the framework of the electronic components, and they make it possible to connect the internal components.

Certification of an Internet of Things (IoT) electronic product is one of the main challenges for tech companies today. IoT products are quickly becoming a part of modern life, and their popularity is encouraging governments to step in and increase their safety regulations.

Converting consumer needs into final product designs is one of the challenges in the product manufacturing process. The design for assembly is essential because it guarantees that manufacturers can remain competitive and satisfy the never-ending expectations of their customers.

Regarding modern technology, the world is expanding extremely quickly, and the results are immediately felt in our day-to-day activities. There is now numerous advanced equipment in use that we could not have imagined in past years. However, with the help of these technological innovations, we get to improve our quality of living.

Huge trade exhibitions are held annually where manufacturers display all of their newest products to spark interest among distributors, dealers, and potential buyers. Many consumers may not realize or even consider the amount of work that went into the creation, development, and launch of the new items.

Change is driven by innovation. A significant number of changes take place every day in fast-paced sectors like the industrial Internet-of-Things (IoT) industry and the high-tech world. No product ever reaches the market without undergoing quite a few design changes along the road, and even products that have already hit the market will probably require regular updates.

What are VECTOR BLUE HUB’s vision and strategy for exponential growth? What’s the fundamental element of our business development plan? To find out the answers to these and other questions, read the newly released interview with our CEO

Find out how you can take your relationship with EMS to the next level. In this ultimate guide we gathered the most significant hurdles that await all companies deciding to seek a new partner for design and manufacturing services.

What are Electronic Manufacturing Services (EMS)? Should you outsource the manufacturing of your electronic products? What are the capabilities of EMS companies? These are questions many CEOs, managers, and entrepreneurs have about the world of EMS. As an industry leader with decades of experience, Vector Blue Hub has prepared detailed answers to your most pressing questions about the electronics industry and the electronics manufacturing process!

As one of the top Electronics Manufacturing Services companies, VECTOR BLUE HUB also offers specialized and affordable electronic PCB assembly services. We have many years of experience and can assure you of 100% quality service.

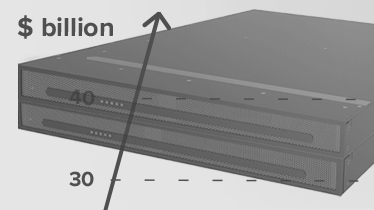

It should be of no surprise that global telecom Electronics Manufacturing Services (EMS) are now in high demand. Television and the Internet connect us all – people, machines and companies worldwide – based on smart electronic and telecom products. Consumers’ choices continue to redefine the Information and Communication Technology (ICT) industry in terms of safer, more accessible and faster methods of communication.

Read the interview with our CEO, Bartosz Kajut and our General Manager, Włodzimierz Babś where they share the story of VECTOR BLUE HUB and explain the unique concept of keeping design and manufacturing services under one roof.

The Industry 4.0 revolution redefines the way people, machines, and companies connect worldwide. Our awareness grows simultaneously with our desire to harness the Internet of Things (IoT) to facilitate data collection, such as by medical devices, wearables running on Bluetooth Low Energy (BLE) or smart devices using Radio-frequency identification (RFID) tags. Here a challenge arises for electronic manufacturing companies, as they need to replace the traditional circuit board with a flexible printed one (PCB).

The pandemic has irrevocably changed the role of supply chain management (SCM) in manufacturing electronic devices. The coronavirus outbreak has exposed all weaknesses of the supply chain in maintaining production continuity and providing component availability. Many companies pursued a business continuity plan to reduce the risk of not keeping to agreed lead-times, but some contract manufacturers were too late to act.

The ability to respond with services that deliver real value to the customer and invest their money wisely is today the most important aspect of Electronic Manufacturing Services. Keeping electronic design and manufacturing under one roof represents the smart approach, one where the customer benefits by being served better, faster and more cost-effectively.

The road to bringing the final electronic products to the mass market can be bumpy and fraught with difficulties. Everything starts with the custom electronics design, where we identify the requirements and establish a set of technological standards such as communication protocols.

Electronic Manufacturing Services (EMS) companies need to make smart decisions that bring real value to the customer, whether in product design, prototyping, or contract manufacturing. With operational excellence, they can achieve the highest levels of agility by doing things better, faster, and more flexibly.

The telco electronics sector is one of the most dynamically growing industries to have made major investments in broadband and internet services in recent years. The need for high capacity has been increasing steadily for years and the COVID-19 epidemic has accelerated global digitization. It is estimated that humankind “leapfrogged” some ten years forward over the past six months.

Product development spending can be a major item in many company budgets. Global manufacturers of electronic devices often have the means to initiate many projects and run them simultaneously, to eventually continue only those that have prospects to do well in the market. Can such an approach continue?

Sketching ideas is one of the first steps that you have to take when designing a product. Of course, it doesn’t just need to be used in a professional design process; this approach is well worth using in the visual presentation and development of any idea. The advantage of sketching is that you don’t have to be a trained artist to create sketches. With them, design concepts can be presented and explained easily.

You’ve got an idea for a new electronic product or even more: you’ve got a complete design for your solution and all you need to launch the product is a reliable partner who will turn your vision into a physical product. There are plenty of companies which provide such services and you are surely wondering what criteria you need to choose the best partner to work with.

A device designed by VECTOR BLUE HUB, an IP-RF signal modulator, marketed as ROTON, has been recognized by the Polish Institute of Industrial Design as one of the most innovative Polish design solutions presented at the exhibition of 25 Polish Design Process Success Stories.

Beacons are one of the examples of how we have transferred the well-known Bluetooth technology from everyday use to the business environment. We could expand their application on a bigger, more usable scale if the location services Bluetooth were more accurate. As it happens, it is already viable (you can track objects down to centimeters), but it needs more sophisticated technology - the technology which takes its beginning in the first steps of designing beacons hardware.

Recently, we went through the subject of working along with the process in companies. It is very wise of an entrepreneur to set the work in procedures (we know that now), but is it wise from the client's perspective to track down paragraphs? Let us keep an eye on what information clients get when they know their services provider sticks to process stages.

Our services

Your close partner

in manufacturing and designing

services for electronic devices