How Through Hole Soldering Works? - Principles and Technique

Is through-hole soldering the best fit for your needs? Learn its principles and technique for successful electronics assembly and make informed decisions.

Table of Contents

- PCB formation: A Foundation for modern electronics

- The rise of Through-Hole Technology

- THT in modern electronics

- Optimizing THT production: The VECTOR BLUE HUB process

- Custom solutions: The VECTOR BLUE HUB approach

- A synergistic approach: Combining SMD, THT, and manual soldering

- Innovations in THT: Adapting to the changing landscape

- Educational value and developmental impact of THT in electronics

- Ensuring reliability in PCB assembly

- Looking ahead: The future of PCB manufacturing technologies

- THT's future prospects

PCB formation: A Foundation for modern electronics

Initially, electronic devices like amplifiers were manually assembled, resulting in complex, tree-like wire structures, but these were mechanically unstable and electrically unreliable. The advent of PCBs revolutionized electronic assembly by providing a stable, reliable platform, greatly enhancing precision and reliability. This innovation paved the way for rapid technological advancements in electronics.

Early PCBs were instrumental in refining soldering techniques, moving from basic soldering iron and wire to advanced methods like through-hole soldering, where component leads are inserted into PCB holes. This method required meticulous soldering to ensure strong connections and avoid problems like solder bridges. The development of soldering tools and accessories further improved the precision and efficiency of soldering, marking a significant progression in the journey towards modern electronics.

The rise of Through-Hole Technology

With the establishment of PCBs came a significant technological leap: the development of Through-Hole Technology (Through hole soldering). This method, where components were inserted through one side of the printed circuit board and soldered on the other, marked a new era in electronics manufacturing. Dominating the landscape of the 1970s and 80s, THT was not just a technique; it exemplified our ability to adapt in the face of new challenges.

The rise in popularity of Through-Hole Technology (THT) can be attributed to several key factors:

- Robustness: THT is known for its robust nature. The physical connection it provides by soldering component leads through the PCB ensures a durable bond

- Ease of Repair: One of the most significant advantages of THT is the ease with which components can be replaced or repaired. This aspect was particularly appealing in an era when electronic devices started becoming commonplace

- Reliability for Various Applications: As electronic devices found their way into diverse areas, from consumer electronics to industrial machinery, THT's reliability became indispensable. It could withstand the demands of various applications

- Durability: THT components are generally more durable compared to their surface-mount counterparts, especially in high-stress environments where mechanical strength and high power is a priority

- Simple yet Effective: Despite its simplicity, THT proved to be highly effective. It allowed for strong electrical connections and mechanical stability, which were crucial for the performance and longevity of electronic devices

-

Foundations for the PCB Industry: THT’s introduction marked a significant milestone in PCB manufacturing. It became a cornerstone technology, symbolizing an era of growth and innovation in the electronics industry.

THT in modern electronics

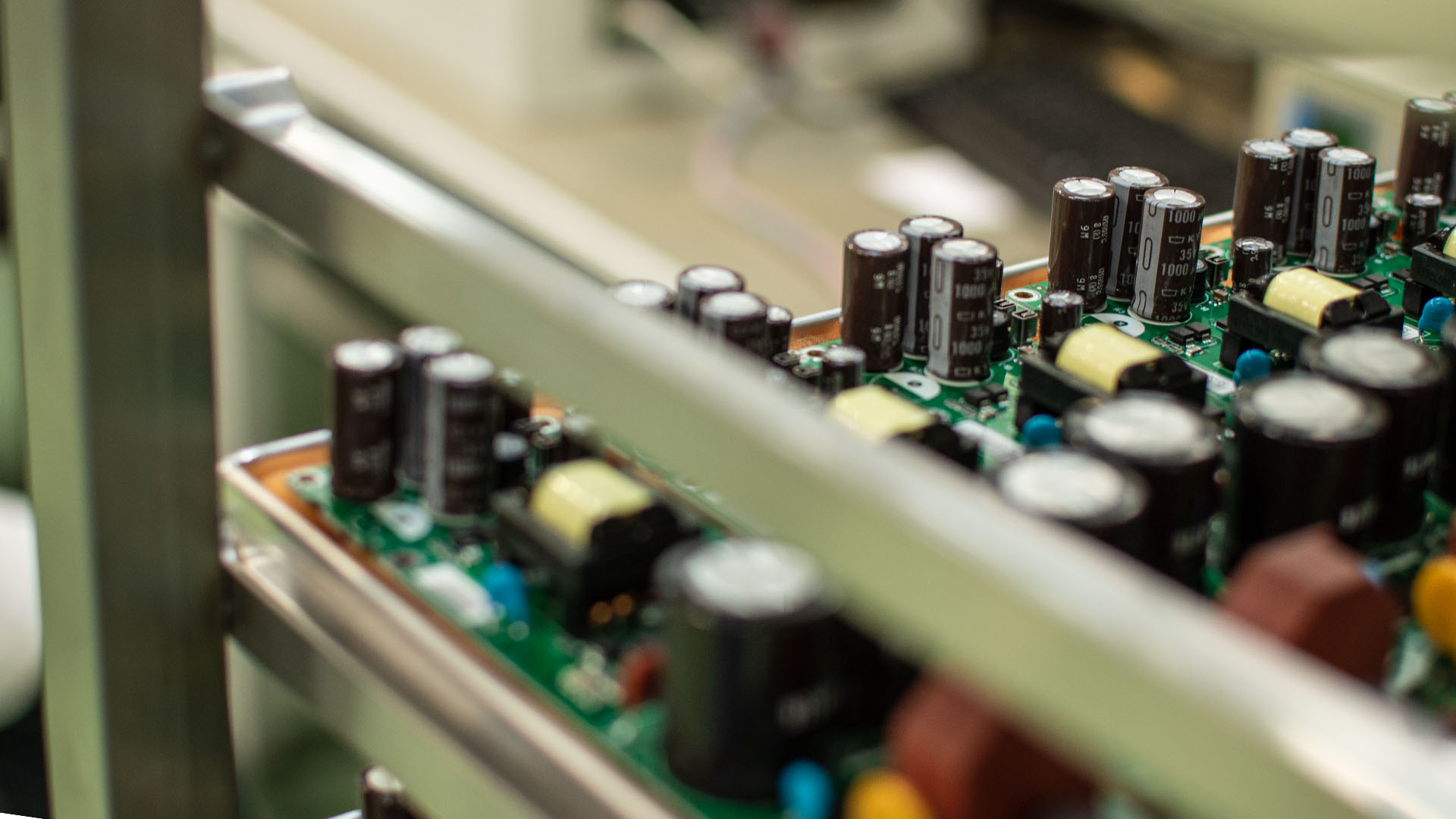

Despite the rise of Surface-Mount Technology (SMD) in the late 1980s, THT remains relevant, especially in high-power applications like generators or power supplies. The heat generation and high current requirements of these applications often exceed the capabilities of SMD components, making THT an indispensable solution.

It happens that the parameters of THT components cannot be reproduced in SMT technology. Through-hole components enable a strong mechanical connection of the elements with the board and high resistance to overheating are particularly recommended for demanding environments.

Optimizing THT production: The VECTOR BLUE HUB process

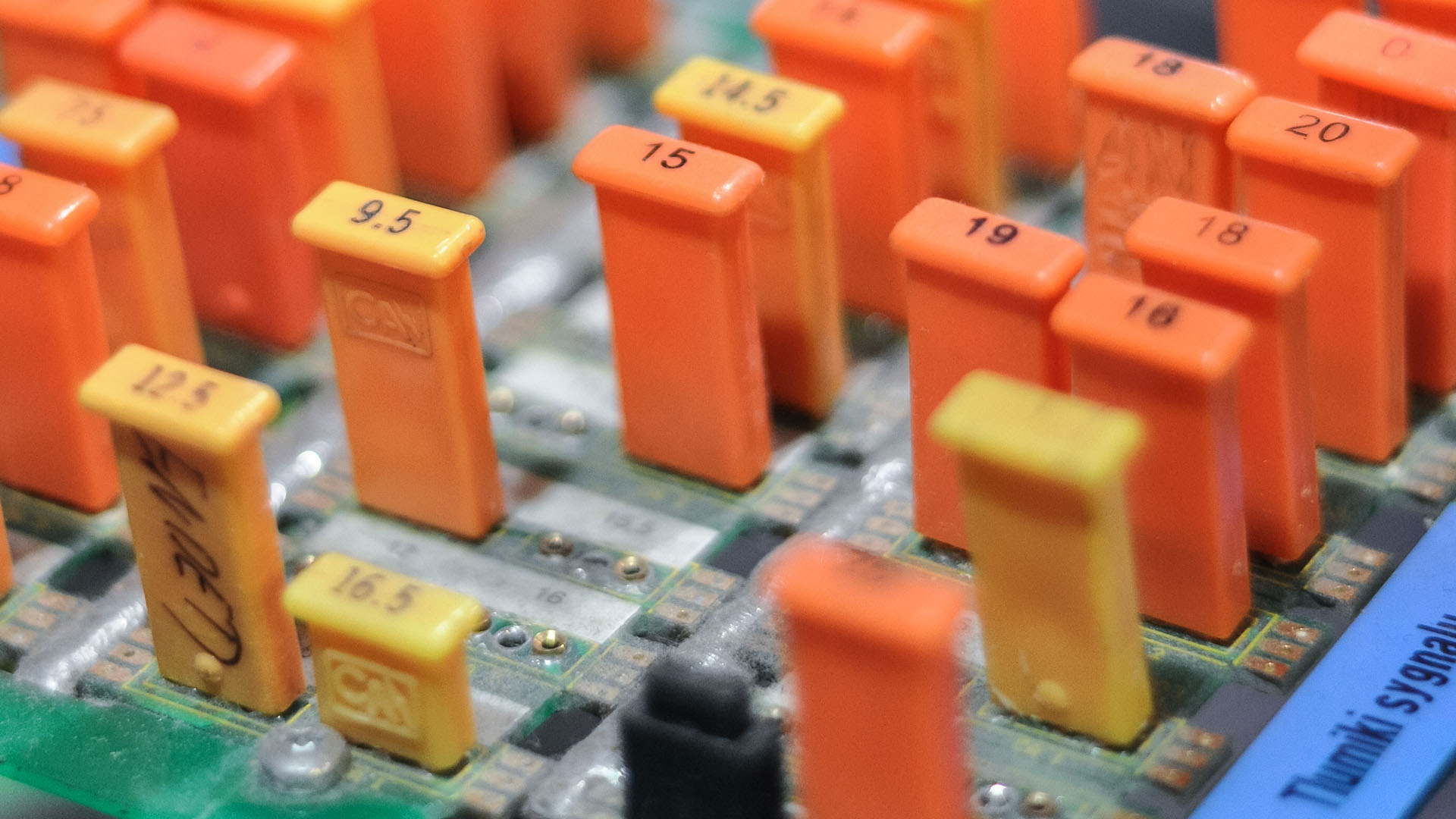

At VECTOR BLUE HUB, the standardization of THT production involves wave soldering at various stations, depending on the complexity of the device. Each operator mounts a specific group of components, guided by descriptive layers on the PCB. The boards then undergo automated soldering, significantly aided by modern lead-free solder waves with nitrogen tunnels that reduce oxidation and facilitate better soldering.

This soldering process ensures that every through-hole component, from axial lead components to radial components, is securely attached, offering a good connection that can withstand the rigors of heavy use. The use of suitable soldering tips and the careful application of solder by experienced staff ensure that issues like solder bridges and excess solder are avoided, maintaining the integrity of each circuit board.

Custom solutions: The VECTOR BLUE HUB approach

At VECTOR BLUE HUB, we provide also customized services, particularly for internal clients needing specialized circuits like data transmission amplifiers or nodes. Untypical, customized components, often featuring intricate designs and delicate cases, are unsuitable for automated processes due to the risk of damage.

Referring to THT technology, we can choose from three methods of soldering components, depending on needs:

- manual soldering - using a soldering iron, properly selected tips and precise tools, this process requires qualified operators using a precisely soldering iron. This customized approach, which involves carefully applying solder wire and using a soldering tip to remove excess solder, meets both specific needs and custom solutions

- wave soldering machine - high and repeatable method of soldering THT components using an automated process, requires experience and skillful adjustment of the thermal profile in relation to the soldered PCB boards

-

selective soldering machine - serial and repeatable PCB soldering, but only specific areas and components on the PCB, soldering is done using a fountain - soldering head. It demonstrates the versatility and adaptability of through-hole soldering (THT) in modern electronics manufacturing.

A synergistic approach: Combining SMD, THT, and manual soldering

Modern PCBs often incorporate a blend of technologies. At VECTOR BLUE HUB, we integrate SMD components, followed by standard THT components that are wave-soldered, and finally, manual soldering for quality verification and adding customized elements.

This approach exemplifies the synergy between different technologies. For instance, SMD allows for efficient use of space and quicker assembly, while THT offers strong mechanical bonds, particularly for axial and radial components that require more heat resistance.

The final stage of manual soldering, using a soldering iron and carefully applying solder, ensures that each component, irrespective of its unique parameters and thermal requirements, is optimally placed and soldered for effective functioning. This method also allows for the inspection of solder joints, ensuring a good connection and avoiding issues like solder bridges or insufficient solder.

The combination of these technologies allows us to cater to a broad range of needs, from heat-resistant pads for high-power applications to delicate circuit boards requiring precise soldering control.

Innovations in THT: Adapting to the changing landscape

Through-Hole Technology continues to innovate, adapting to modern requirements. Recent advancements include the use of more sophisticated soldering irons and iron tips to ensure better heat conduction and control. The introduction of flux pens and brass sponges in the soldering area has improved the application of solder and maintenance of the soldering tip.

Innovations in solder materials, such as flux core solder wire and lead-free solder, have enhanced the quality of solder joints. With these advancements, THT remains relevant, particularly for axial lead components and radial components, which require the mechanical strength that THT provides. Modern THT also incorporates wave soldering techniques, which efficiently solder multiple through-hole components, ensuring that each component lies flat and is securely attached.

Educational value and developmental impact of THT in electronics

The educational significance of Through-Hole Technology (THT) in the realm of electronics is an often under-discussed yet vital aspect of its legacy.

- THT offers students and aspiring engineers a practical way to learn the basics of circuit design and soldering techniques.

- The straightforward approach of THT in component placement and soldering is perfectly suited for those just starting to learn about PCB assembly.

- THT provides a fundamental understanding of how PCBs are designed and assembled, making it a valuable educational tool in electronics.

Moreover, the developmental impact of Through-Hole Technology (THT) extends beyond individual learning. It has spurred innovation in educational kits and DIY projects, making the world of electronics accessible to hobbyists and enthusiasts. These kits often use THT components, allowing users to build and understand circuits from the ground up. Working with elements like solder paste and iron tips, users receive a comprehensive learning experience in assembling electronics. This approach not only makes electronics more understandable, but also inspires creativity and innovation, encouraging individuals to explore and experiment with electronic designs.

Ensuring reliability in PCB assembly

Quality control and testing are crucial in PCB assembly, ensuring that each solder joint meets rigorous standards. A good solder joint is characterized by sufficient solder that forms a smooth, shiny connection without excess solder or too much heat applied, which can cause damage.

Inspection methods often involve checking for solder bridges, insufficient solder, or excessive heat that could compromise the component body or the surrounding insulating materials. For through-hole soldering, it's essential to verify that the solder fully fills the plated vias and creates a secure bond with the component leads.

In contrast, surface mount soldering requires inspecting the alignment and connection of the metal components to the printed circuit board. Advanced techniques, individual thermal profiles in soldering processes and also the use of agents improving the esthetic and appearance of the solder contribute to the overall reliability of the PCBs. A clean and aesthetic soldering point improves the ability of inspection and quality verification. It confirms the correctness and reliability of the manufactured PCB.

In our PCB assembly process, each stage rigorously adheres to the IPC 610 standards, ensuring top-tier quality and reliability. These standards guide our inspections, focusing on solder joint integrity, component alignment, and avoiding damage from excessive heat or insufficient solder, thereby guaranteeing the excellence of our products.

Looking ahead: The future of PCB manufacturing technologies

As we look towards the future, PCB manufacturing technologies are poised for further advancements. The focus is not only on refining through-hole and surface mount techniques but also on integrating new materials and processes.

Expectations include:

- the development of more heat resistant pads

- innovative soldering methods effectively tailored to the needs of the project.

Additionally, there's a growing interest in environmentally friendly materials and processes, such as more efficient use of lead-free solder and reduced reliance on harmful chemicals. The future may also see a greater emphasis on automated soldering processes, capable of handling a mix of through-hole and surface mount components with precision and consistency. With these advancements, the PCB manufacturing industry is set to meet the ever-increasing demands of modern electronics, driving innovation and efficiency to new heights.

THT's future prospects

Through-Hole Technology (THT) remains a fundamental component in PCB manufacturing, especially relevant in high-power and specialized applications. Its significance is anchored in the durability and reliability of each solder joint, a testament to the effectiveness of through-hole soldering. This technique, which precisely connects components to the PCB using solder, creates the solid mechanical and electrical connections necessary in a variety of electronic applications.

As the electronics industry continues to evolve, THT's legacy stands as a symbol of innovation and adaptability. At VECTOR BLUE HUB, we blend traditional THT methods with advanced soldering technologies to meet our clients' diverse needs. This approach not only honors THT's historical contributions but also adapts it for contemporary and future applications, ensuring its continued relevance in the ever-advancing field of electronic manufacturing.

Jarosław Krzyżanowski

Jarosław has over fifteen years of experience in electronics manufacturing processes (SMT, THT, AOI, X-RAY, SOLDER WAVE, SELECTIVE, ASSEMBLY). As Process Leader, he ensures an appropriate level of skill in the manufacturing staff, work standards, processes, the appropriate workplace infrastructure, tools and the best use of technological solutions. He gets the most satisfaction out of teamwork. He also likes to look for out-of-the-box innovative solutions our customers require. Music is Jarek’s greatest passion; he also loves family walks and DIY.