We make your process effortless, with our specialized PCB Assembly service!

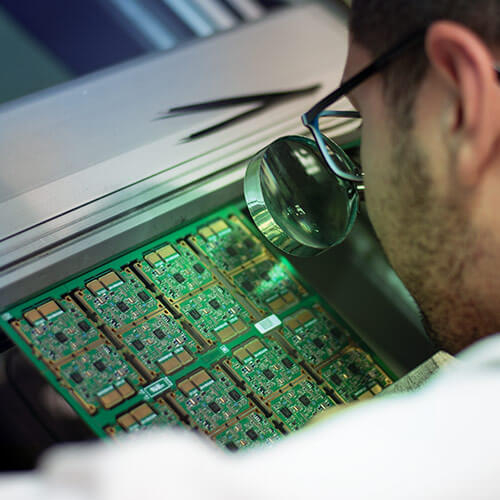

As one of the top Electronics Manufacturing Services companies, VECTOR BLUE HUB also offers specialized and affordable electronic PCB assembly services. We have many years of experience and can assure you of 100% quality service.

At VECTOR BLUE HUB, we have many years of experience and assure you of 100% quality electronic PCB assembly service. We have worked with various customers and Original Electronics Manufacturers (OEMs), and we pride ourselves on getting fantastic work done every time. You can completely take your hands off the electronic PCB assembly when you work with us -from component procurement, mounting, physical soldering, and testing.

Our team of skilled and qualified PCB assembly experts is always ready to do your work while filling you in on every process along the line. You also get PCB design and assembly done in an appropriate time -a satisfactory turnaround time. Let's look at what our typical PCB manufacture and assembly service involve.

What exactly is PCB Assembly?

PCB assembly is a manufacturing process involving the designs and production of Printed Circuit Boards used in many electronics like refrigerators, dishwashers, and sound systems. It follows the design and assembly stages of a custom PCB project. PCB assembly is the process of connecting electronic components to the printed circuit boards (by using soldering).

At Vector Blue Hub, our PCB assembly solutions have a fast delivery time, ranging from simple prototyping to large-scale production.

What are the main methods of PCB Assembly?

There are two primary methods of PCB assembly (which we offer at Vector Blue Hub). They are Surface Mount Technology (SMT) and Through-Hole Technology (THT).

Surface Mount Technology

Surface Mount Technology (SMT) involves soldering components directly onto the board's substrate in their required locations. SMT assembly is usually used for applications that do not need robust mechanical bonds on the finished PCB.

With surface mount technology, your PCB's components are affixed to the board's surface using solder paste, as opposed to the older and more traditional practice of inserting wires through holes in the board. With SMT assembly, the electronics components are much smaller, potentially permitting a reduction in the size of your board.

It is also a faster assembly process than THT, and can be optimized using a Pick And Place PCB assembly machine to prepare all the components accurately before soldering. Electronic components designed for SMT layouts are cheaper than those for THT builds. SMT is often more suitable if you want to assemble PCBs, but prioritize cost and space.

Through-hole Technology

Some components cannot be surface mounted, so through-hole technology assembly is used to affix them to the board. It involves placing the pieces by hand and inserting their metal wires through holes on the board. The reverse side of the board is soldered to keep the wires in place.

It takes longer to produce a finished PCB using the THT method because other processes are needed during the design and manufacturing phases. THT PCB manufacturing services (soldering) can be done manually, or automatically using a dedicated Insertion Mount Machine.

Electronics components designed for THT are larger and slightly more expensive than their SMT counterparts. This is partly because they need to be made with the essential conductive 'legs' so they can be inserted and connected through the PCB substrate.

Regardless of your intended method, your aim is a PCB that you can rely on, to perform efficiently in its assigned role. We pay attention to excellent craftsmanship, experience, quality tools, and other details at Vector Blue Hub. Never hesitate in contacting us if you have more questions about the main assembly methods.

Our electronic PCB Assembly Services

We work successfully for our customers in various industries and develop a personalized strategy at every phase of the PCB prototype and assembly process. Here's what we offer:

- Surface Mount Technology assembly

- Ball Grid Array (BGA) inspection and verification

- Post-flow Automatic Optical Inspection (AOI)

- 8-zone force air convection reflow oven

- Through-Hole Technology (THT)

- PCB box build assembly services

- Lead-free wave soldering

- SMT rework and repair

- Fully-tailored test and programming services

- Sub-module Cable Potting

- Complex electro-mechanical assembly

- Electro-pneumatic assembly

- High and Low volume PCB assembly service

Why choose us as your PCB assembly contract manufacturer?

Our values at VECTOR BLUE HUB are honesty and openness. We strive to build a long-lasting relationship with all our clients. We prioritize your needs and satisfaction. Our team of experienced engineers has been working in this field for years, and is the best you can get. Over the years, we have maintained a reputation for being competitive, reliable, and affordable.

We give you the best quality products and services. We also allow testing during the process. All products are available at inexpensive prices, according to the individual sizes, labor costs, and quality.

We can assure you that you have chosen to work with a reliable, experienced, and devoted electronics manufacturing partner.

Customer satisfaction is our number one focus! Your quality is assured through every job!

For more details on our full range of state-of-art PCB services, including PCB design prototyping, simply explore this page for the FAQs section. Alternatively, you can always contact us for a free quote.

Frequently Asked Questions (FAQs)

What does PCB assembly mean?

PCB assembly means Printed Circuit Board assembly. It consists of the design and assembly stages for a custom PCB project. The soldering process connects the electronic components to the PCB.

Can I use my EMS partner for the assembly?

Yes you can! Vector Blue Hub also offers Contract Electronics Manufacturing Services, so you can hire us for EMS and PCB assembly. Contact us if you have specific requirements.

What files are needed for PCB assembly?

A number of design files are required to carry out a smooth and risk-free printed circuit board assembly. In addition to the files required for assembly, the most essential are the Gerber files, Centroid doc, assembly drawings and Bills of Materials (BOM). A Gerber file is a set of files used to construct different layers of a PCB, to be used for the production process. Each layer needs a separate Gerber image file. The centroid file (also called the ‘pick and place’ or ‘XY data’) is used for programming PCB assembly. This file includes the information about the orientation and placement of all surface mount parts, including the reference designator and X and Y positions. The BOM plays a vital role in the PCB assembly process. It contains the index of components and raw materials that should be assembled explicitly on the PCB. A PCB manufacturer depends on the BOM information to build a product.

Do you offer testing options?

Yes we do! Depending on your needs and specifications, we provide testing options for this service. This comprehensive and functional testing option allows you to validate the entire assembly process.

How do I get a price for my PCB assembly project?

You can book a free consultation with us here to get your project price. You will need to prepare your requirements so we can get everything right.

Whether you order our bare boards or the whole electronic PCB assembly service, we guarantee the best you can find in the industry. We can cater for your tailored specifications while prioritizing quality and service.