Demystifying Electronics Manufacturing Services (EMS) - frequently asked questions

What are Electronic Manufacturing Services (EMS)? Should you outsource the manufacturing of your electronic products? What are the capabilities of EMS companies? These are questions many CEOs, managers, and entrepreneurs have about the world of EMS. As an industry leader with decades of experience, Vector Blue Hub has prepared detailed answers to your most pressing questions about the electronics industry and the electronics manufacturing process!

The electronics industry is constantly advancing, and EMS manufacturing providers like us need to grow to play a vital role in its evolution. Here's a walk-through of the whole process.

What is Electronics Manufacturing Services?

Electronics Manufacturing Services (EMS) are preferred by companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and offer the assembly of products for Original Equipment Manufacturers (OEMs). This concept is known as Electronics Contract Manufacturing (ECM) or Contract Electronics Manufacturing (CEM).

EMS Companies provide a wide array of manufacturing services including automotive electronics manufacturing, supply management, technical support, and aftersales support. EMS providers can be hired at different stages in the manufacturing process.

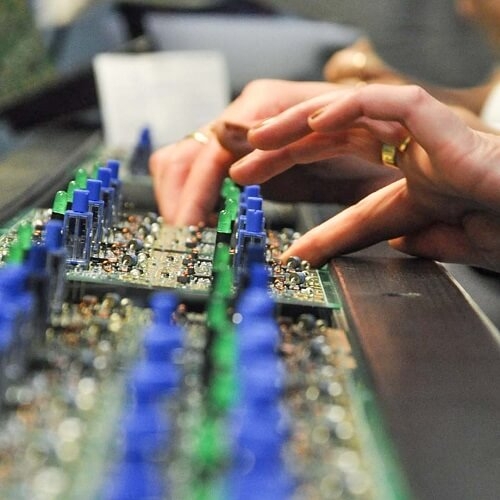

If you already have a design for a product you wish to develop, you can contract EMS companies to manufacture, assemble, or test the product. EMS companies may provide additional onsite services such as PCB (Printed Circuit Board) etching. They can also deal with contractors to provide additional services on a case-by-case basis to meet the needs and requirements of the client.

What Are Common Terminologies and Acronyms in the EMS World?

EMS processes are innately complex, and this is only compounded by the fact that the industry has a language of its own with many acronyms, technical terms, and verbiage. This can be difficult to navigate for beginners - here's a list of the most common terms to get you started!

ATE – Automatic Test Equipment

This machine was invented to conduct various tests on electronic components, especially when working with high-volume production.

CEM – Contract Electronics Manufacturers

A CEM is a company responsible for a slew of tasks from designing to manufacturing on behalf of and in partnership with an OEM.

EMS – Electronics Manufacturing Services

The services provided by a CEM to an OEM are typically called electronics manufacturing services.

OEM – Original Equipment Manufacturers

The term for a company that designs, sells, and distributes its products by itself.

PCB – Printed Circuit Board

A device that mechanically helps and electrically links electronic components using conductive tracks, pads, and other features etched from copper sheets.

What are the Tiers of the Electronics Manufacturing Industry?

The EMS industry is generally divided into tiers, which primarily reflect the size and revenue stream of the company. The tiers go from 1 to 4. Tier 3 and 4 companies are typically smaller companies, while Tier 1 and 2 firms are larger ones.

Size isn't always reflective of quality, however. Tier 3 and 4 companies can provide EMS electronic manufacturing services that are just as comprehensive as their Tier 1 and 2 counterparts. In fact, smaller EMS providers are typically leaner with lower overheads and less bureaucracy, which makes them ideal partners for entrepreneurs and startups!

What can Electronics Manufacturing Services Companies Do?

The capabilities of EMS providers are often misunderstood. Though the original service they offer is printed circuit board assembly(PCBA), due to innovation and technological advancement, EMS providers' job description has expanded quite considerably.

Nowadays, many EMS providers offer comprehensive processes combining PCBA, cable harnesses, box build, and testing. This is a complete package, meaning the OEMs get exhaustive offers, giving them the ability to almost entirely disengage from production processes.

The capabilities of EMS engineering companies vary from one another. With Vector Blue Hub, you can expect these services and more:

- PCB assembly

- Cable assembly

- Electromechanical assembly

- Electronics design

- Contract manufacturing

- Test and Validation

- Prototyping

- Aftermarket services

- Conformal coating Repair and revision upgrading

- Burn-in and thermal cycling

- Product certification

Why Did Electronics Manufacturing Services Take Off?

While the electronics industry was in its infancy, OEMs used to do everything in-house. Demand was low, electronics were simplistic, and supply chains were straightforward, delegating tasks didn't make a lot of economic sense.

As the industry grew, the need for dedicated electronic manufacturing services grew with it. The first EMS provider was founded in the 60s, and by the 80s, it had taken the industry by storm with many prominent OEMs selling their manufacturing plants in favor of working with EMS providers.

Due to economies of scale and specialization, EMS providers could reduce manufacturing costs while freeing up talent and manpower in OEMs for other tasks. Today, whether you're a startup or a large firm, if you want to manufacture a product and bring it to the market, you generally have to partner up with an EMS provider.

Best Practices When Starting a Partnership with an EMS Provider

A partnership with an EMS provider can be decades long, determining the trajectory of your business. It is not a choice to take lightly. There are a few industry best practices you should follow to increase the chances it is productive:

- Communicate, communicate, communicate: Electronic manufacturing is complex and a partnership with an EMS provider is multifaceted; there's a lot of room for miscommunications and misunderstandings. To ensure the partnership starts on the right foot, you need to properly communicate your needs, set your expectations, and outline your requirements: Manufacturing details, quality control, production volumes, deadlines, etc. A deal should only go forward if you agree on the details!

- Ensure clear contract terms: Clear contract terms, ownership rights, and exit clauses ensure both parties understand what they're responsible for and are entitled to while preventing future misunderstandings. It is one of the ABCs of entering into any business partnership, and it certainly holds here as well!

- Collaborate: Giving up control over part or the whole of the manufacturing process can certainly be scary, and it does involve risks, but the benefits of partnering with an EMS provider have been clearly demonstrated, and this needs to factor into your business approach. Communicating with, collaborating with, and integrating the EMS provider into your company's processes will yield results!

- Play to your strengths: Most CEMs provide comprehensive services that go well beyond manufacturing, including designing, aftersales support, supply chain management, marketing, and more. An ideal partnership will have your company working on aspects of the business where it is the strongest while delegating tasks where it lacks expertise or manpower to the CEM!

What Are the Challenges that Face Electronics Manufacturing?

The electronics manufacturing industry is constantly evolving with ever-fresh challenges and obstacles. Here are the biggest challenges facing OEMs:

- Short Product Life Cycles: The lifecycle of consumer electronics is increasingly shorter with customers ever following "the latest trends". Companies need a fast manufacturing process and decreased time to market if they want to adequately compete!

- Emerging Market Competition: Competition in the consumer electronics market, increasingly from emerging markets, is stiff, and if current trends hold, it will only continue to do so in years to come. Businesses need to provide quality products at competitive prices.

- Variable Raw Material Costs: The cost of raw materials is unstable and increasingly variable. This makes it hard to project production costs over the medium and long term. The environment advantages a lean manufacturing process that can be tweaked on the fly.

- Unreliable Supply Chains: COVID laid bare weaknesses in global supply chains, and though things have improved considerably since, there are still chokepoints and constraints that companies, even large multinational ones, have to contend with. Companies that know how to navigate supply chain constraints and build more durable, reliable supply lines can more easily capitalize on changes in the market.

- Support and warranty: Demand for support and better warranty terms has increased in recent years. This is compounded by social media where faulty products might go viral and generate a lot of negative press for companies. Companies need to be able to handle the extra cost of providing proper support and warranties.

If you want to partner with an EMS provider, the company needs to be plugged into the electronics market, aware of the latest challenges, and capable of providing proper solutions to address them. It takes two to tango, and without your EMS provider being fully on board, you can't take the steps necessary to tackle these issues!

What Are Key Future Trends in the Consumer Electronics Industry?

The fast-paced and highly competitive nature of the electronics industry doesn't bring with it just new challenges and obstacles, it also brings opportunities that companies can exploit to great success.

Though predicting trends, especially in such a highly volatile industry, is a bit of tea leaf reading, paying attention to current and emerging trends is still worthwhile:

- Artificial Intelligence: The elephant in the room - AI is already making its mark on the electronics industry. It is being used to speed up prototyping, detect faults during production, and enhance various functionalities of the end product. It even has an impact on consumer demand patterns. It is hard to predict where advances in AI will lead the electronics manufacturing industry, but companies simply can't ignore it!

- Interconnectivity and IoT: Electronic products are increasingly interconnected and capable of taking advantage of the Internet of Things (IoT), 5G, and other communication protocols. From designing the printed circuit boards to marketing the products, companies need to pay attention to how their products can be used in conjunction with and as a complement to other electronics!

- Wearable Technology: With electronic components becoming smaller, the trend of wearable technologies has only accelerated. Recently, for example, the market for smartwatches saw exponential growth. Wearable technologies provide portability, constant access, and convenience, all highly desired by consumers today. Companies can position themselves better by capitalizing on this trend!

- Sustainability: Due to government policies, reduced recycling costs, and global energy cost increases, sustainability will be the name of the game for many industries going forward. Electronic manufacturing able to take advantage of recycled materials and capable of producing minimal waste will have an increasing edge in the medium term.

- Social Responsibility: The perception towards companies is changing with consumers not only expecting great products but wanting the company to give back to the community through initiatives, charity donations, etc. This pressure only increases as the company becomes larger and more successful. Companies aware of these dynamics and capable of employing them to bolster their image and strengthen their brand will see benefits.

What Kind of EMS Provider Should You Hire?

Choosing the right EMS provider can be the difference between success and failure in the consumer electronics industry! From product design to production costs, quality control, supply chain management, and aftersales support, they are all directly influenced or dictated by the EMS provider.

If you need electronic devices manufactured to your standards and needs in a timely and efficient manner, you have to choose the right EMS provider.

Here are some of the qualities of a good EMS (electronics manufacturing services) provider you should be on the lookout for:

Proven Track record

Electronic manufacturing is a complex, multistage task that requires extensive research and prototyping to succeed. Experienced electronic designers need to oversee the entire process. In short, only an EMS provider with experience and a proven track record is capable of meeting your requirements and standards! Checking the company's prior projects and portfolio will give you an idea about their manufacturing processes and capabilities!

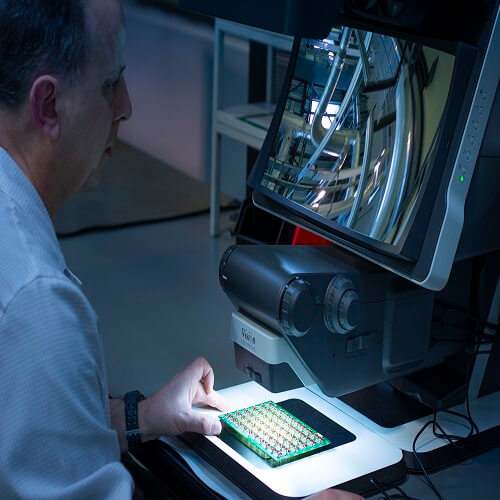

Testing Methodology

Success in the consumer electronics industry is all about building a brand. If a consumer is going to pay $100, $200, or $500, they need to be sure it has low failure rates and is covered by a generous warranty. It is the EMS provider's job to ensure the reliability of the products, and this can only be done through a proper testing suite that identifies failures in real time in all aspects of production.

Proper quality control includes environmental testing, functional testing, and reliability testing among others. When choosing an EMS partner, always ask about their approach to testing and product reliability.

Timely, Scalable Production

Ensuring your electronic products hit the shelves on time and in adequate volume is key to maximizing revenue. Delays will not only make your company incur reputational damage, but they will also make it unable to capitalize on market demand to boost profits.

A partnership with an EMS provider is long-term, often spanning decades. Sadly, as market conditions and business plans change, many EMS providers are unable to meet deadlines and don't have the infrastructure necessary to expand production in line with your consumers' expectations.

Before you sign the contract, make sure the EMS provider has the infrastructure necessary to meet your current and future needs!

Comprehensive Services

A partnership with an EMS provider isn't solely about the electronics manufacturing process. A lot of secondary services can be part of the deal: supply management, new product introduction (NPI), aftersales services, and more. An EMS provider can be your partner from the designing and prototyping stage to marketing.

What services does your company need? Is your EMS provider of choice capable of delivering them? These questions should inform your choice!

How Does Vector Blue Hub's Electronic Manufacturing Services Measure Up? Why Should We Become Your Partner?

From a proven track record to a skilled workforce and the use of cutting-edge technologies, Vector Blue Hub has it all. Our products are manufactured to the highest industry standards and our engineers are capable of taking over all the processes including designing, prototyping to final assembly!

If you're looking for a trustworthy EMS provider, here are just a few reasons why Vector Blue Hub is the one:

Skilled and experienced workforce

The modern electronics manufacturing process is highly intricate and complex. OEMs require a highly skilled workforce, the prerequisite infrastructure, and a slew of support systems (excellent customer service, advanced manufacturing, and engineering expertise).

It is hard for OEMs to do everything themselves! This is where EMS providers come in. OEMs can focus on other parts of the production processes while reducing costs and easing the stress of managing a daily production environment by delegating work to electronics manufacturers.

We are very qualified, reliable, and accessible: Our team's expertise and diverse skill sets allow us to complement your approach and meet your needs. You can play to your company's strengths while leaving the rest of it to us!

Timely Supply

EMS providers are responsible for ensuring products make it to the market in due time. Production delays can cause losses and reputational damages. This is unacceptable, and it is why Vector Blue Hub has its electronics manufacturing process designed around ensuring there are absolutely no delays in production!

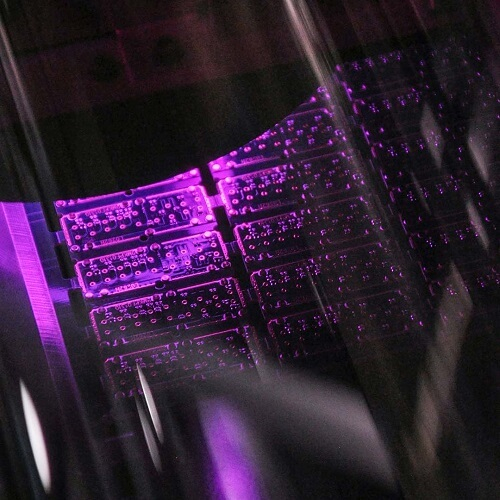

Advanced Technologies

Thanks to the use of cutting-edge manufacturing processes, surface mount technology, and industry best practices, Vector Blue Hub is capable of producing highly competitive electronics, in terms of both features and price. Check out our equipment, processes, and portfolio for more details!

Direct Fulfillment Services

We offer comprehensive direct fulfillment services, including troubleshooting and reshipment. We directly work with clients to find a cost-efficient and time-saving solution.

Industry Compliance

Vector Blue Hub can meet national and international industry compliance requirements thanks to a thorough and mature quality control strategy. Our products are always to the clients' standards and specifications.

Vector Blue Hub's Associated Services

Aside from offering comprehensive manufacturing services at the highest quality standards, we also offer a host of associated services aimed at ensuring our partners' success:

New Product Introduction (NPI)

New Product Introduction (NPI) is one of the most vital processes in electronic product development, and we're here to help our partners! We offer to carry out a thorough evaluation of a new electronic product before mass production. The detailed processes we conduct to ensure that the product is fit for the market include DFMA Design for Manufacturing and Assembly methodology, DFT Design for testability analysis, MEA Failure Mode Effect Analysis risk analysis, and Certification support.

Sourcing and Supply Chain Management

We offer sourcing and procurement operations at VECTOR BLUE HUB. We carefully vet every supplier to ensure our stringent reliability, quality, and affordability standards. We optimize electronic production services costs to help OEMs achieve business goals comfortably.

Engineering Services and Product Management

VECTOR BLUE HUB is also experienced in offering engineering support services like product management and testing. Our services include Engineering Change Order (ECO) management, Alternative Materials Management, and Design for Manufacture and Assembly.

The Best Electronics Manufacturing Services Provider: VECTOR BLUE HUB

What makes us extraordinary? Our unique under-one-roof approach, where the design and electronics manufacturing processes are in one place, allows us to cut down on costs and speed up manufacturing! Our core values are transparency, responsibility, high quality, and good business relations. We are the EMS company that will help streamline your plans and bring them to the market!

Contact us and our team of experienced, skilled, and reliable experts will be available to get in touch ASAP! We're always available to talk about ways we can make your project a reality! Book a free consultation here and we'll reach out.