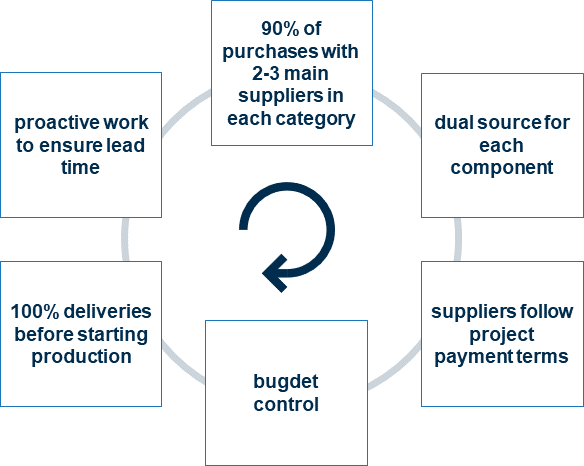

How Supply Chain Management Services (SCM) Work at VECTOR BLUE HUB

Supply chain management is a complex process. It involves planning and execution of your supply chain activities, from procurement to delivery, inventory management, warehousing, and transportation. Moreover, the global economic disruption has irrevocably changed the role of supply chain management (SCM) in manufacturing electronic devices.

In recent years, many companies have realized the importance of supply chains strategy as they started implementing them in their production systems. Here at VECTOR BLUE HUB, our goal is to build an ecosystem of relationships with suppliers that will allow for rapid development and delivery of high-quality services.