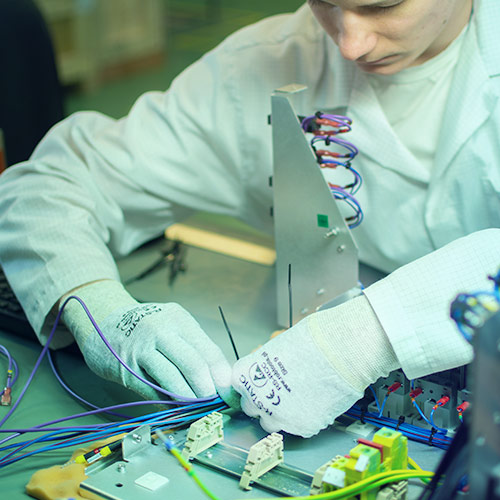

By making use of our engineering expertise, we guarantee our customers a competetive advantage

Engineering services are the backbone of any product development. They include the process of conceptualizing, designing, and developing a product. To achieve this goal, we have an experienced team of engineers who will work with you to create a feasible solution.

Our engineering services are backed by our expertise in various fields, such as mechanical, electrical, automation, and software. We also offer product management services to help you manage your products from conception to delivery.

We use various tools and methodologies to ensure our customers receive the best quality engineering services, including agile methodology for development projects.