Understanding the Adaptive Supply Chain

The COVID-19 pandemic accentuated the fragility of the global supply chain, forcing businesses worldwide to confront the urgent need for greater resilience in their operations. Despite awareness of the risks posed by natural disasters and geopolitical events, the pandemic emphasized the critical need for a more adaptive approach to supply chain management. The reality is that supply chain disruptions are inevitable and can arise from various unforeseen events. To navigate these challenges, companies must embrace the adaptive supply chain, utilizing advanced cloud-based technologies to ensure preparedness for any scenario.

Reports also show that 75% of manufacturing firms sourcing from China during the pandemic faced significant disruptions. The extensive network of global supply chains has led to a heavy dependence on specific regions for essential components and raw materials.

To meet these evolving challenges, businesses must build resilience in their supply chains. These measures will enhance visibility and responsiveness, ensuring that supply chains remain potent in the face of future disruptions.

This article aims to provide a comprehensive knowledge of how adaptive supply chain management can safeguard business continuity and drive long-term success. By understanding and implementing adaptive supply chain management, businesses can better prepare for future challenges, ensuring continuity and stability in an unpredictable world.

Defining the concept: Adaptive Supply Chain

An effective adaptive supply chain must account for the multiple layers of risk and threats impacting modern supply chains. At its core, supply chain adaptability is the capability to adjust the design and operations of a supply chain in response to structural shifts, disruptions, and evolving customer behaviors. This involves modifying supply networks to reflect these changes and ensuring stability and crisis resistance.

Adaptive supply chain management leverages advanced insights into supply chain dynamics, complexity, and uncertainty to build resilience. A key characteristic of an adaptive supply chain is its capacity to respond to fluctuations in demand quickly. This requires the use of real-time supply chain data and analytics to monitor market conditions and make necessary adjustments to production and logistics processes. This enhances supply chain adaptability and ensures that the business strategy remains robust in a volatile business environment.

Managing and mitigating risks is another critical aspect of adaptive supply chains. Cybersecurity investments are also essential to protect supply chain networks from cyber threats, ensuring operational efficiency and business continuity.

Sustainability is also integral to the adaptive supply chain. Companies must aim to reduce their environmental impact and promote ethical practices throughout their global supply chain. This might involve adopting green logistics practices, such as using electric vehicles for delivery and ensuring compliance with environmental and labor standards across all suppliers.

Incorporating digital technologies like artificial intelligence and blockchain can further enhance supply chain processes by improving visibility and responsiveness. By leveraging business intelligence and refined insights, companies can better navigate the complexities of global supply chains, ensuring they remain resilient and adaptable in the face of ongoing disruptions.

Limitations of the traditional Supply Chain

Supply chains face numerous challenges that demand innovative solutions. Geopolitical events, natural catastrophes, and pandemics continue to disrupt operations, necessitating effective crisis management strategies. There is an increased demand for transparency and traceability of products, which many organizations must address to maintain consumer trust.

Rapid technological advancements and the adoption of new digital technologies require companies to stay agile and responsive. Labor shortages and rising labor costs add further complexity while ensuring cybersecurity in the face of growing cyber threats is critical. Compliance with new regulations and trade policies also presents significant burdens.

Additionally, there is growing consumer demand for sustainable and ethically sourced products. E-commerce and digital platforms offer both challenges and opportunities, compelling supply chains to adapt and respond quickly. These challenges underscore the need for adaptive supply chain strategies that incorporate flexibility in sourcing new suppliers, and the integration of new technologies to remain competitive and resilient.

What are the benefits of an adaptive supply chain business strategy?

The traditional supply chain strategy, characterized by its linear structure focused on speed, cost, and quality, often lacked the flexibility to swiftly adjust to internal and external changes. In contrast, the adaptive supply chain thrives within a digital ecosystem of trading partners and customers, enabling organizations to pivot quickly in response to disruptions, evolving customer demands, or new regulations. This approach offers a multitude of benefits:

- Enhanced Responsiveness: The Adaptive supply chain strategy enables companies to swiftly respond to variations within their internal environment, ensuring that operations remain smooth and efficient.

- Dynamic Network Redesign: These supply chains allow organizations to continually adapt and redesign their supply networks to meet external changes, such as market shifts or regulatory updates.

- Customer-Centric Adaptation: With real-time data, businesses can better identify and respond to changing customer preferences and demands, ensuring higher satisfaction and loyalty.

- Optimized Inventory and Logistics: Improved inventory management and logistics ensure optimal business performance, reducing waste and enhancing efficiency.

- Agile Supplier Management: Companies can more effectively identify, onboard, and manage suppliers and partners, ensuring a resilient and flexible supply base.

- Innovation Driven by Feedback: Real-time feedback from the supply chain fosters business and product innovation, allowing companies to stay ahead of the competition.

- Execution Capability Understanding: Clear insights into manufacturing and supply chain processes enhance execution capabilities, leading to better overall performance.

- End-to-End Visibility: Full supply chain connectivity provides unprecedented levels of end-to-end visibility and transparency, crucial for informed decision-making.

- Sustainability and CSR: Adaptive supply chains bolster sustainability and corporate social responsibility efforts, promoting ethical practices throughout the supply network.

Transitioning to an adaptive supply chain strategy requires leveraging advancements in digital technologies. These benefits are maximized when a business fully integrates digital solutions, sharing information and collaborating electronically with suppliers, customers, and partners. Embracing an adaptive supply chain model not only enhances operational efficiency but also fortifies a company's ability to navigate an ever-changing business industry.

Leveraging Adaptive Strategies for Market Success

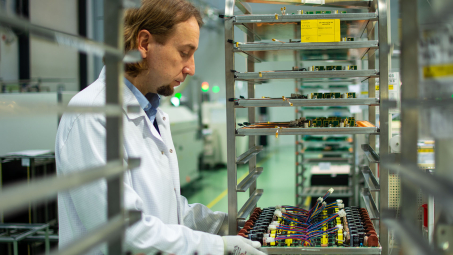

VECTOR BLUE HUB, a leader in electronic manufacturing, has shown remarkable resilience in a challenging market by embracing flexibility and adaptability. Our dedicated team handles critical situations, ensuring we are prepared for unexpected challenges. Streamlined processes allow our technologists and designers to quickly implement solutions, while strategies like negotiating better prices and redesigning products help mitigate rising production costs.

Efficient supply chain management, effective communication, and flexibility are key to our success. This adaptive strategy is crucial to our work, allowing us to maintain high standards of production and innovation. By prioritizing these values, VECTOR BLUE HUB thrives despite market challenges. We invite you to partner with us, where our commitment to adaptive supply chain management ensures your business benefits from our resilience and expertise in a dynamic industry.