Exploring comprehensive Electronics Manufacturing Service options: The benefits of keeping your choices open

Bringing together design and manufacturing under one roof marks a big leap forward in turning ideas into real products. This smart move does more than just save time; it drives innovation, making it faster and easier to bring new, high-quality products to market.

By bridging the gap between the drawing board and the assembly line, companies unlock unprecedented levels of efficiency, agility, and quality control, setting the stage for products that not only meet the market's demands but redefine them.

Embrace the journey of innovation where design meets manufacturing. Discover the full potential of your choices in EMS services!

Table of content

What is the integrated approach to design and manufacturing?

The integrated approach to design and manufacturing combines both processes to streamline product development, lower costs, and enhance quality.

Electronics manufacturing services

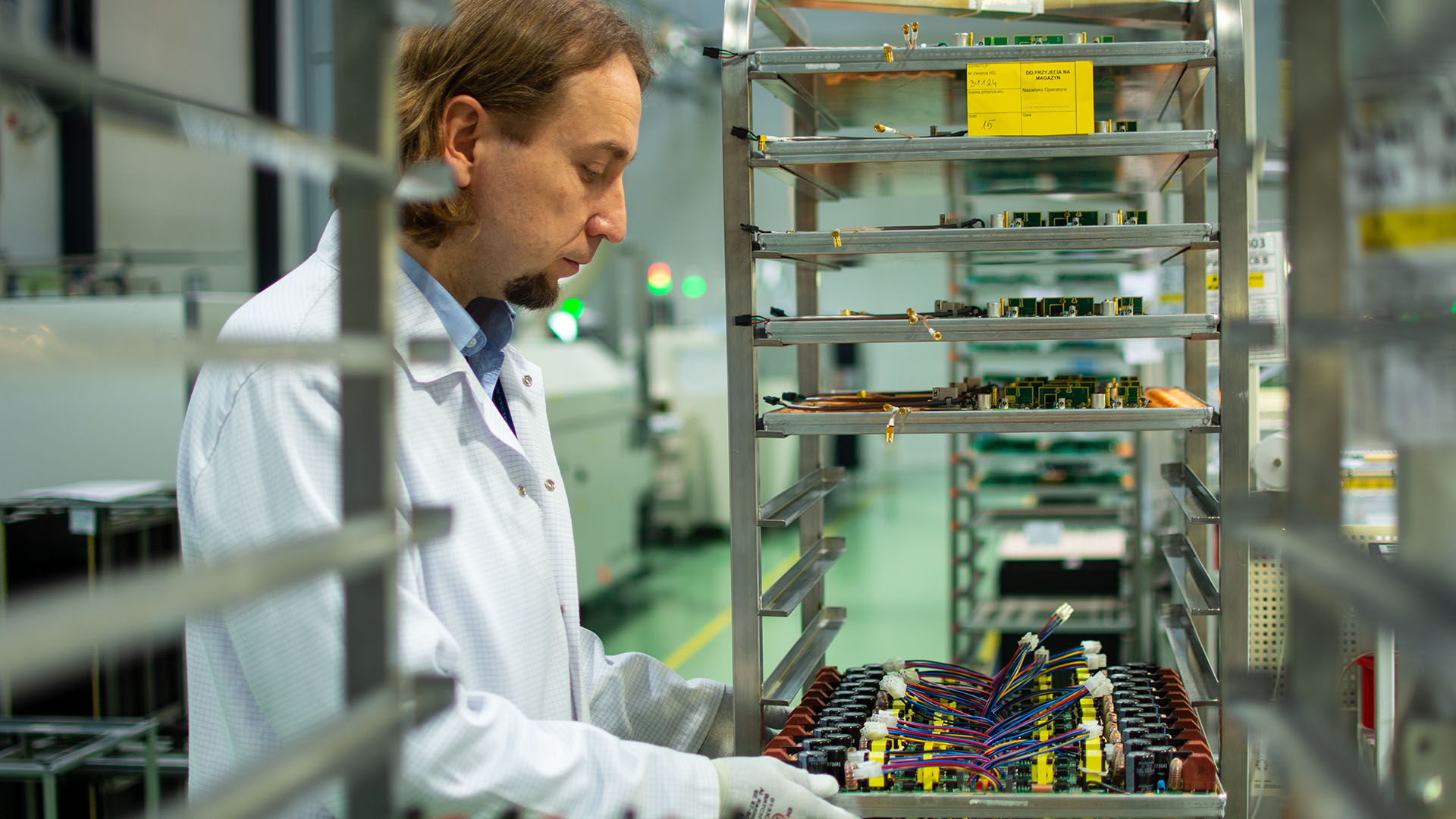

Electronics Manufacturing Services (EMS) offer a broad spectrum of services that facilitate the production of electronic components and assemblies. This includes everything from printed circuit board (PCB) assembly and testing to complete product assembly, packaging, and logistics. EMS providers specialize in a range of manufacturing processes, such as surface mount technology (SMT) assembly, through-hole manufacturing, and flexible circuit assembly. They also provide value-added services like design for manufacturability (DFM) advice, which helps optimize product designs for easier, more cost-effective manufacturing.

In addition, EMS can encompass prototype development, enabling rapid testing and iteration before full-scale production. Quality assurance is another critical service, involving rigorous testing protocols to ensure that every product meets stringent standards before it reaches the market. Beyond manufacturing, EMS often includes after-sales support and repair services, completing the full lifecycle support for electronic products.

Electronics design services at a glance

Electronics design services involve the design of hardware for analog and digital circuits, components, devices, and systems, with a focus on energy or information transmission. The services can range from simple control circuitry to complex multi-board electronic design projects, covering everything from inception to fully assembled and tested production quantities.

Design and manufacturing under one roof - the concept explained

At its core, the integration of design and manufacturing is a strategic approach that facilitates:

- Regular updates in technology and design to meet evolving customer demands

- Streamlined product development

- Reduced costs

- Improved quality

- Help companies maintain profitability in an increasingly competitive market.

A comprehensive integration of design with manufacturing allows businesses to get an instant quote and:

- Scale swiftly

- Boost innovation

- Build a knowledge base for future projects

- Prevent downtime

- Optimize material usage

- Ensure that designs are production-ready

-

Increase profitability

Advantages of the hardware design and mass manufacturing under one roof approach

The integration of electronic design, including PCB design and schematic capture, and manufacturing under one roof allows for refinements and enhancements throughout the production stages. This can lead to a potential combination of parts for cost and time savings, proving to be crucial for scaling production efficiently and overcoming production bottlenecks, as seen in the context of the global semiconductor shortage.

The use of advanced design tools that enable simultaneous design and manufacturing processes is a key aspect of this approach. Such tools can help:

- Identify and prevent errors, misalignments, and tolerance issues early on

- Improve quality by enforcing standards and preventing assembly problems

- Lead to high-quality parts production without trial and error

Ultimately, an integrated approach to manufacturing and design can prevent delays, unnecessary expenses, and quality issues, thereby enhancing an organization’s competitiveness. In essence, manufacturing and design are increasingly viewed as interconnected elements within a single design process.

Why you shouldn't limit your options

In a nutshell, integrating design and manufacturing under one roof is a comprehensive strategy that offers multiple benefits. It streamlines product development, reduces costs, and improves quality, thereby enhancing the competitiveness of businesses.

The use of advanced design tools and effective collaboration between teams forms the backbone of successful integration. This approach is further bolstered by the adoption of Design for Manufacturing principles, which optimize product designs for ease of production and cost reduction.

As businesses continue to navigate the realms of technological innovation, the integration of design and manufacturing has emerged as a winning strategy. It offers a scalable, profitable, and efficient way to meet customer demands, making it a key player in the journey towards business success.

Connect with a reliable and experienced EMS partner

At VECTOR BLUE HUB, we seamlessly integrate electronics design and manufacturing services, offering a comprehensive solution that encompasses the following advantages:

- Easy to manage: Focus on your core business with confidence, knowing that your EMS partner is expertly handling everything else.

- Less capital investment: Save on the costs associated with developing a manufacturing or R&D center and on training and retaining employees.

- Manufacturing scalability: Easily expand your production capacity to meet the demands for larger volumes.

- Quick Time To Market (TTM): Experience reduced design and volume production times thanks to overlapping selected phases.

- One-stop shop: Benefit from support in product certification, ensuring your product's quality meets international standards and complies with safety regulations.

Choose VECTOR BLUE HUB for a partnership that goes beyond expectations. Contact us today!

Jarosław Krzyżanowski

Jarosław has over fifteen years of experience in electronics manufacturing processes (SMT, THT, AOI, X-RAY, SOLDER WAVE, SELECTIVE, ASSEMBLY). As Process Leader, he ensures an appropriate level of skill in the manufacturing staff, work standards, processes, the appropriate workplace infrastructure, tools and the best use of technological solutions. He gets the most satisfaction out of teamwork. He also likes to look for out-of-the-box innovative solutions our customers require. Music is Jarek’s greatest passion; he also loves family walks and DIY.