A Beginner's Guide: How to choose a PCB assembly company

Choosing the suitable PCB assembly manufacturer is not easy - it's like finding the perfect recipe for your favourite dish. You want all the right ingredients, precise measurements, and a dash of expertise to ensure the end result is not just good but exceptional. Much like cooking, assembling a PCB requires a blend of precision, technology, and reliability. And just as every cook has their own style, every PCB assembly company has unique strengths, specialities, and production capabilities.

Also, by the time you've reached the assembly stage of the printed circuit board manufacturing process, you've invested a lot in your project. It's a critical phase that can significantly impact your product quality. In the electronics industry, PCB assembly bridges the gap between design and a functional, market-ready product. The PCB components' placement and connection hold immense importance, emphasizing the significance of choosing the right PCB assembly company.

If you're outsourcing assembly, finding the perfect partner becomes paramount. However, the abundance of options and the gravity of this decision can make the selection process rather daunting. However, with the right guidance, making a good choice is attainable. In this article, we’ll walk you through the fundamental aspects to consider when selecting a PCB assembly company.

What Does A Typical PCB Assembly Process Entail?

To find the perfect PCB assembly companies, understanding what goes into this complex process is crucial, particularly concerning your project's unique needs. So, what exactly is PCB assembly? It's the key stage in PCB manufacturing where a bare board is adorned with the electronic components necessary to transform it into a functional printed circuit board. These components are the heart of the printed circuit board, turning it into the vital circuit that powers an electronic product. The assembly processes of a PCB commonly occur through one of two methods:

Surface Mount Technology (SMT)

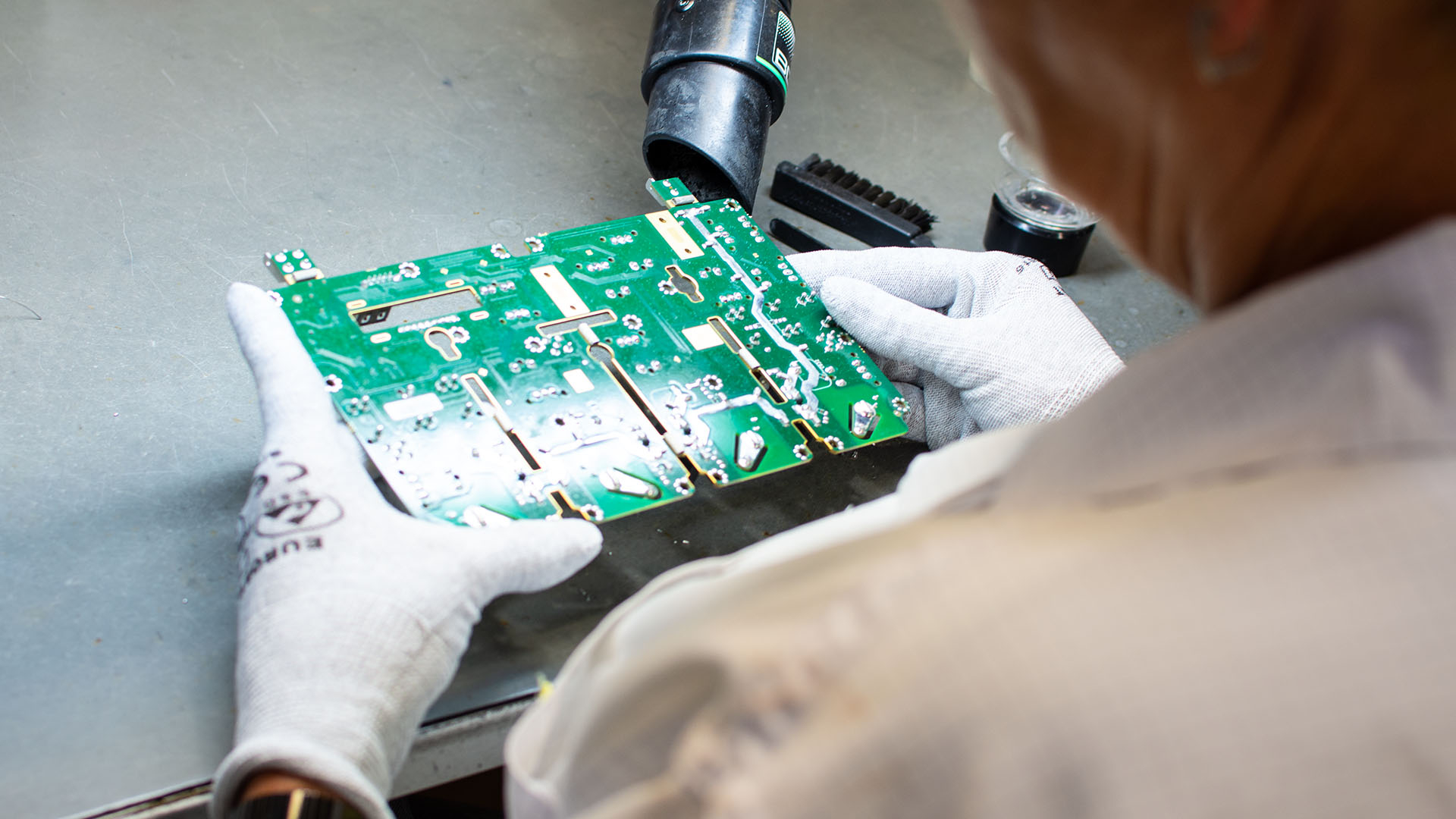

This method is very popular, especially for smaller and more lightweight boards. In this process, tiny electronic components are placed directly onto the board with the help of automated pick-and-place equipment. It's a bit like carefully positioning Lego bricks on a surface, but in this case, it's about positioning the components perfectly on the printed circuit board, making the assembly process faster and more efficient.

Surface-mount assembly is the top choice for most boards because it's quicker, more cost-effective, and enables the creation of smaller, lighter products. It also allows for higher connection densities, meaning you can fit more on a smaller surface.

Through hole manufacturing

This process involves drilling holes in the board, inserting components through these holes, and then soldering them onto the opposite side of the board. This method takes a bit more time and can cost a little extra, but it's incredibly strong. It is ideal for tasks that demand extra strength or work in harsh conditions.

If your project requires heavy-duty performance or will face extreme conditions, through-hole technology might be your best bet. However, for the majority of cases, surface-mount technology is the preferred option due to its efficiency and versatility. Sometimes, for specific applications, a combination of both methods might be employed to harness the strengths of each for a more tailored solution. On a single product, you may even combine the two approaches.

How to choose a PCB assembly company: 10 easy steps to find the right PCB assembly partner

1. Understand your Product's Unique Needs

When seeking the right PCB board manufacturer, a key factor is to grasp your project's unique needs comprehensively. This involves determining the specific PCB technology your project demands, whether it's through-hole manufacturing, surface mount, or a combination of both. Additionally, confirm if the PCB assembly manufacturers can accommodate the precise size requirements of your boards, as not all suppliers can manage all dimensions.

Define your budget for the project, considering that pricing structures can vary among manufacturers. Identify the necessary safety and compliance certifications required for your industry, ensuring that the electronics equipment manufacturer can meet these standards. Specify the number of boards needed, as some manufacturers might have minimum order requirements. Determine if you require supplementary PCB assembly services such as wire harnesses or assistance with ray tracing.

Finally, decide on the level of finishing services required, whether it’s comprehensive services like box build or turnkey PCB assembly services, or if labour-only services suffice for your project's specific needs. Understanding these key aspects beforehand will significantly streamline your selection process, guiding you toward a PCB manufacturer best suited to fulfil your project's unique criteria.

2. Conduct an in-depth research

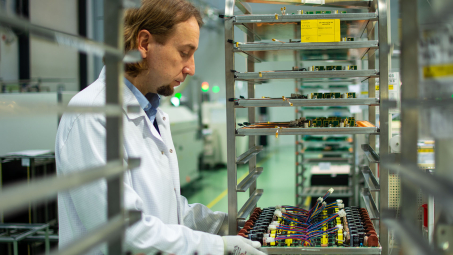

Once you've identified your project needs, narrow down 3-5 potential PCB assembly partners to find a reliable company. Evaluate their experience, focusing on their history in your industry, years in business, and additional services offered. Confirm their proficiency in surface-mount or through-hole technology and their capacity for various board sizes.

Check if they possess the necessary equipment for the job and ensure they conduct PCB assembly in-house, avoiding outsourcing. Thorough research is key; prioritize reliability over low prices, seeking a partner that aligns with your ideals and maintains project timelines.

Also, identify the manufacturer's production capabilities to your project's specific requirements. Companies tailored for huge quantities might not handle smaller quantities effectively. Conversely, smaller companies focused on prototype PCBs or small production quantities could be overwhelmed by large orders. Assess the manufacturer's capacity and ensure it aligns with your project's scale, whether it's for small-scale prototyping or larger production runs. This match ensures smoother operations and better outcomes for your PCB assemblies.

Experience matters greatly -Look into a company's background via its website or direct communication to understand its capabilities and project history. Ask about their services, industry tenure, and clientele to match their experience with your project requirements. Consider suppliers offering additional services like component procurement or supply chain management. Seek alignment between the partner's experience and your project needs.

3. Evaluate Product Quality and Confirm Testing Services

Quality and adherence to regulatory standards are important in any electronic assembly. When choosing a PCB assembly company, ensuring they have adequate quality testing services and quality control measures is essential.

For the manufacturing plant, look out for certifications such as ISO 9001, which pertains to quality management systems, ISO 14001 for environmental management, and OHSAS 18001/ISO 45001 for occupational health and safety. These certifications demonstrate the plant's commitment to maintaining high-quality standards, environmental sustainability, and a safe working environment.

Assessing the quality of products before delivery can be challenging. Look for indicators such as the equipment used; top-notch machinery often correlates with superior results.

Client feedback offers insights into a company's quality standards. Investigate past work and seek customer reviews for a comprehensive view. Exploring testing options is crucial; inquire about their testing procedures and company-wide quality control processes. An ideal PCB assembly company offers visual inspections, automated optical inspections, and custom testing plans.

Ultimately, the goal is to select a PCB manufacturer with rigid quality control systems and comprehensive testing protocols. These measures ensure that your project undergoes the necessary array of tests, from functional testing to detailed inspections.

4. Check out for reliable customer support

Beyond technical ability, the significance of reliable customer support cannot be overstated. A dependable PCB assembly company prioritizes your needs, promptly addresses queries, and offers effective solutions in case of issues. Assessing a company's customer service can begin during conversations with its representatives. Note their responsiveness, knowledge, and courtesy, along with the speed of their replies.

To gain deeper insights, explore online reviews, and testimonials on their website, third-party review sites, and social media platforms. Observing their interactions with clients on social platforms might reveal more about their customer support approach. Inquire directly with the representative about their support services. Are they willing to collaborate on tailored assembly and testing routines? This flexibility is crucial, especially when selecting the best assembly technique for your project. Additionally, ensure they offer assistance in troubleshooting technical PCB problems, demonstrating a commitment to resolving issues promptly and efficiently.

5. Compare costs

When considering a PCB assembly partner, cost remains a key factor impacting your bottom line while ensuring quality products remain affordable for your customers. Understanding the cost dynamics in printed circuit board assembly involves various factors:

- Order Size: Larger orders often come with bulk pricing benefits, offering savings per unit despite the initial higher cost.

- Services Requested: Costs vary based on assembly types like through-hole manufacturing or surface-mount technology. Additional expenses may arise if you require extra testing, design assistance, or component procurement from the assembly company.

- Resources Provided: Providing necessary components for assembly yourself could be a cost-effective approach, potentially reducing expenditure.

- Labour Costs: More intricate projects usually incur higher labour costs due to the increased complexity and expertise required.

- Shipping Costs: Varying distances, order sizes, and shipping options offered by the assembler contribute to fluctuating shipping expenses.

While cost is important, it shouldn't be the sole consideration. Prioritize quality even if it means a slightly higher initial investment, as it often translates to long-term benefits. Striking a balance between quality and budget is vital. Collect quotes from potential partners, assessing costs and the value they offer. Opt for an option that aligns best with your requirements and financial limitations.

6. Opt for the best PCB Manufacturer for your project

Now that you’ve meticulously compared the PCB assembly manufacturers on your shortlist, it's time to make the crucial decision. By now, you should have a clear understanding of the process, requirements for kickoff, and the subsequent steps.

Considering all the essential qualities we've discussed, VECTOR BLUE HUB is an exemplary choice. Our commitment to customer support, evident through our custom assembly and testing routines, aligns perfectly with your project's needs.

Also, our cost-effective approach, offering competitive pricing without compromising quality, assures value for your investment. With a strong emphasis on client satisfaction, VECTOR BLUE HUB is set to be the ideal PCB assembly partner for your project, ensuring a seamless and successful collaboration.

Jarosław Krzyżanowski

Jarosław has over fifteen years of experience in electronics manufacturing processes (SMT, THT, AOI, X-RAY, SOLDER WAVE, SELECTIVE, ASSEMBLY). As Process Leader, he ensures an appropriate level of skill in the manufacturing staff, work standards, processes, the appropriate workplace infrastructure, tools and the best use of technological solutions. He gets the most satisfaction out of teamwork. He also likes to look for out-of-the-box innovative solutions our customers require. Music is Jarek’s greatest passion; he also loves family walks and DIY.