Maximizing Efficiency with PCB Box Build Assembly Services

When it comes to electronic manufacturing services, then integrated, fully functional products are our ultimate goal. This is why the final assembly and box-build capabilities complement our contract manufacturing services.

Looking to reduce costs and increase efficiency in your electronic manufacturing? Click here to read more and discover our PCB Box-build Assembly Services!

The science behind box build assembly - where electronics become tangible

The demand for complex electronic products continues to rise, and Original Equipment Manufacturers (OEMs) are under increasing pressure to meet customer demands for high-quality products that are delivered on time and at competitive prices. Outsourcing non-core activities, such as PCB box build assemblies, is a strategic approach many OEMs have adopted to remain competitive.

In the fast-paced world of electronics, achieving efficiency and simplicity is crucial for success. PCB box build services offer you a convenient solution by delivering a ready-to-use assembly and reducing the need for multiple vendor logistics. You can choose from a range of enclosure options, including simple plastic or custom sheet metal enclosures, depending on the capabilities of the manufacturer and vendor partners.

The popularity of this kind of service is on the rise due to our ability to streamline the manufacturing process, reduce costs, and speed up the time to market.

What is a Box Build Assembly service?

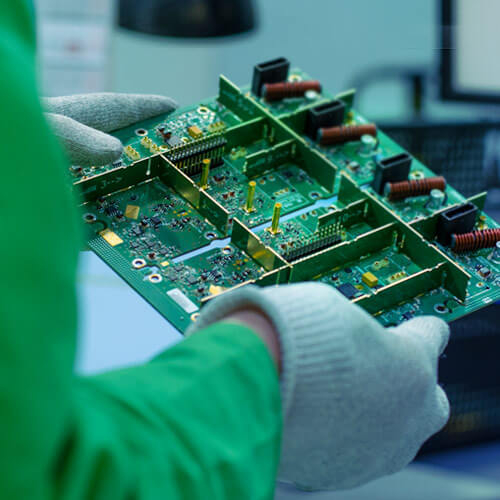

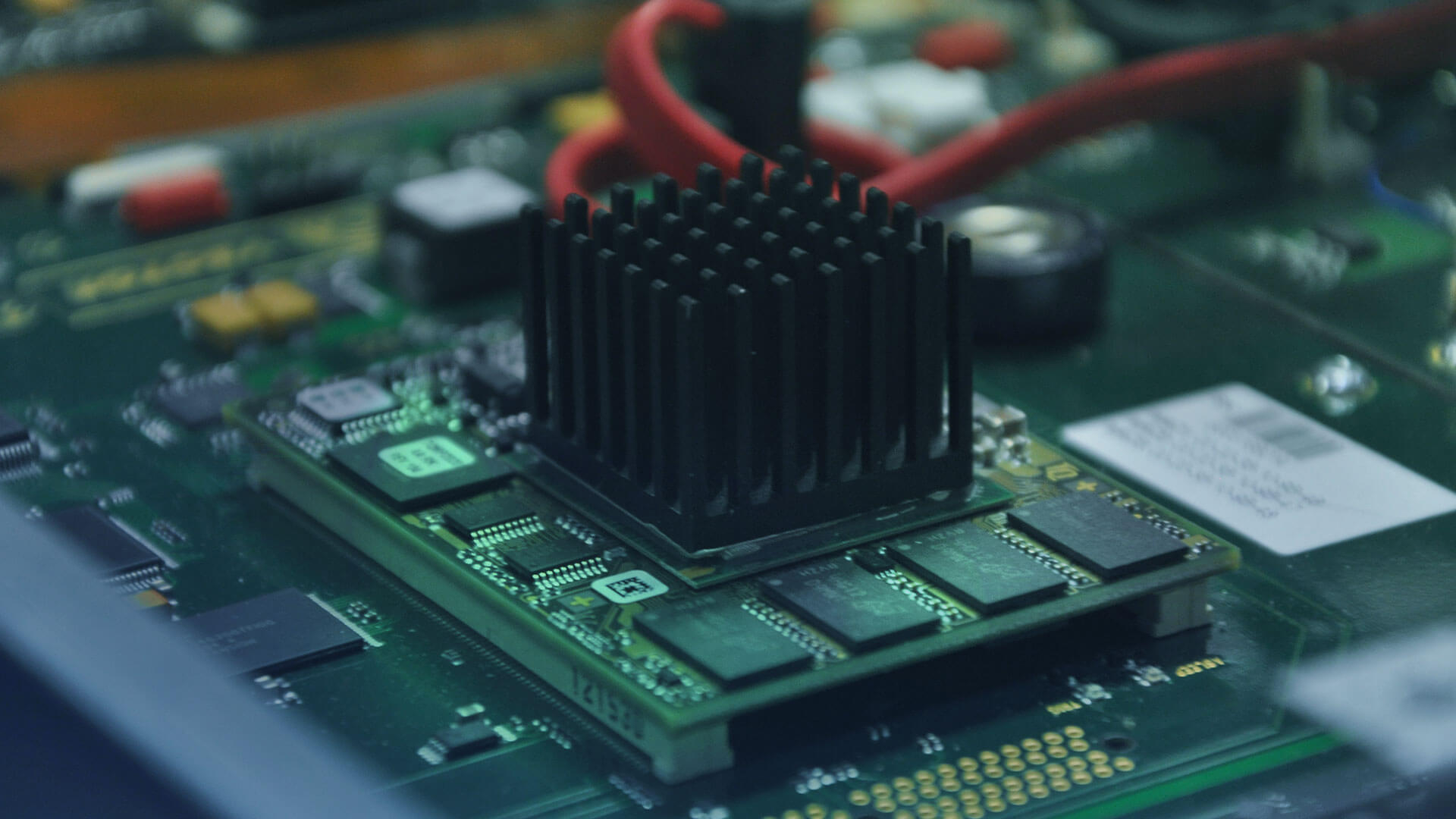

Box build assembly involves integrating electronic components, mechanical parts, cables, and other necessary items into a fully functional product housed in a custom-made enclosure.

Outsourcing this process to a reliable Electronics Manufacturing Services (EMS) provider benefits OEMs significantly.

What does the box build assembly process involve?

The box build assembly process is customized to meet the specific project requirements, and the complexity of each step can vary accordingly. The box build process involves several steps to create a complete system, which may vary depending on the project requirements.

One step might include installing sub-assemblies, such as power supplies or motors, while another may involve installing other essential components, such as sensors or switches. Wiring and cable routing are crucial steps in the box-build assembly process. Cables and wiring harnesses must be precisely routed to ensure efficient and reliable operation.

Same as the fabrication of enclosures - they protect the equipment from external factors, such as water, dust and physical damage. The design can vary from simple plastic to complex sheet metal enclosures, depending on the project requirements. The fabrication of enclosures may involve several manufacturing techniques, including injection molding, vacuum forming, and sheet metal fabrication.

Ultimately, the box-build assembly process aims to create a complete and functional product that meets all the project specifications and requirements.

Why is it worth outsourcing PCB box assembly services?

Cost savings

By leveraging the economies of scale, OEMs can procure materials and components at lower costs, which are then passed onto the customer. Additionally, EMS providers can optimize the production process, minimize waste and increase yield, leading to further cost savings.

Improved quality

EMS providers have experience assembling complex products and expertise in best practices and quality standards. They also have the processes and procedures to detect defects early in the production cycle, leading to a lower defect rate and higher reliability.

Faster time-to-market.

EMS providers manage the entire process, from component procurement to final assembly and testing, resulting in a shorter lead time for product launch. This can be crucial for OEMs looking to stay ahead of the competition and meet the demands for faster product delivery.

Final Assembly and Box-Build Capabilities

The final assembly and box-build capabilities here at VECTOR BLUE HUB are essential our turnkey electronics manufacturing solutions. The expertise in the box-build area includes sub-modules, cables and harnesses, potting and gluing, complex electromechanical assembly, electro-pneumatic assembly, and other project-dedicated assembly cells and lines.

We have well-trained and experienced operators who are vital in providing high-quality assembly services. They stay focused on designing and using production aids, poka-yoke, fault-proofing jigs and fixtures to ensure the highest quality work.

Additionally, at VECTOR BLUE HUB we stand out from other electronic manufacturing service providers with the right technical culture, great attention to detail, and 5S rules for tidiness, orderliness, cleanliness, standardization, and discipline.

Choose VECTOR BLUE HUB for complex assembly services!

You can expect integrated, fully functional products when working with VECTOR BLUE HUB for box-build services, thanks to our final assembly and box-build capabilities.

Box-Build Assembly Expertise

We possess comprehensive skills in box-build assembly services, which encompass a range of tasks:

- mechanical design, supplier evaluation, and tooling project management for mechanical enclosures of various types, including sheet-metal, die-cast or plastic-molded enclosures.

- CNC machining services for customized mechanical parts, such as drilling and threading.

- integration of PCBAs within chassis, button and display assembly, and interfacing.

- assembly of mainboards with daughter-boards, power supplies or battery assemblies. Our proficiency in gasket assembly, gluing, potting, and ingress protection (IP) assembly is also noteworthy.

- final configuration and software updates for a seamless and satisfactory experience.

At VECTOR BLUE HUB, our final assembly and box-build capabilities ensure that you receive integrated and fully functional products. Now it is time to take your hands off the assembly process and trust that our skilled professionals can handle everything with precision and care!