Why Outsource Electronic Design Services? - Smart or Not?

When it comes to creating electronics, it's a complex world with numerous processes to navigate. As a product owner aiming to launch your innovations, you have two options: either manage every aspect of the development process yourself, provided you possess the expertise and resources or hire an external electronic design company. However, for most business owners looking to make a smart choice, the strategic approach often involves capitalizing on your strengths while delegating tasks where your expertise may be limited.

Outsourcing electronic design isn't just for startups. Even big companies do it to lighten their workload and save resources. Whether you're just starting out or a well-established business, tapping into outside expertise isn't just about convenience. It's a way to work smarter, using specialized skills to make better products. By letting experts handle specific tasks, businesses can channel their internal focus towards innovation, market strategy, and core competencies, creating a setup where everyone performs at their best.

In this post, we'll brief you on what electronic design service companies do and why outsourcing offers more benefits than in-house development.

What does an electronic design company do?

Electronic design companies are your one-stop destination for turning your ideas into electronic products.They handle everything from creating printed circuit boards (PCBs), making prototypes, and getting your electronics ready for mass production.

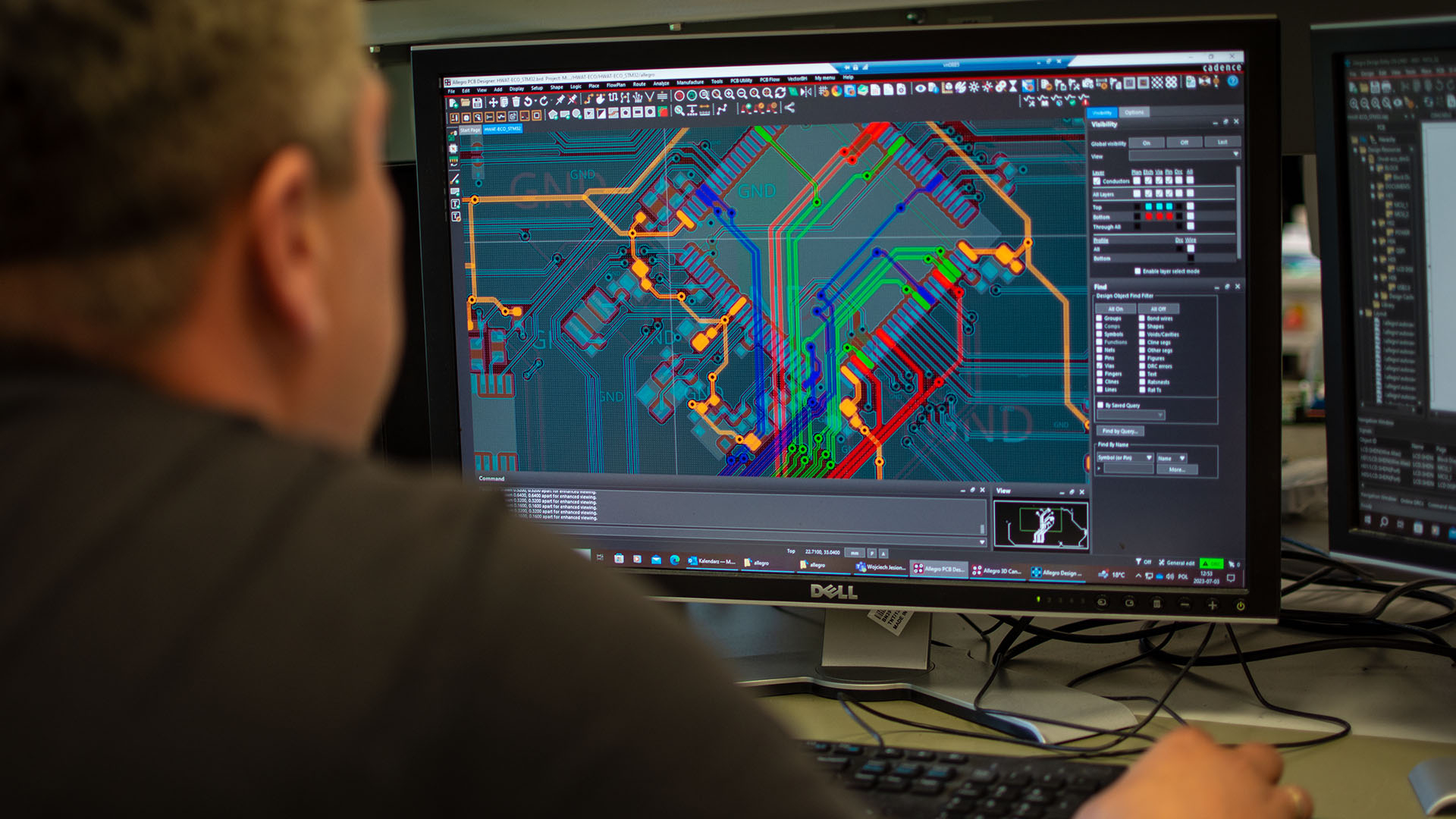

Their expert engineering team provide a range of services, starting from designing how the electronics will work to laying out the actual printed circuit board (PCB layout). They're skilled at creating prototypes, testing to ensure everything works right, and getting the necessary certifications for your product.

Their expertise could span various stages of electronic product development stage:

- Schematic Design: This involves drawing up plans and blueprints for how the electronics will work.

- PCB Layout: They handle the arrangement and design of the printed circuit boards, making sure all components fit and work together.

- Prototyping and Assembly: These companies help create initial versions of the device and put them together for testing.

- Testing and Certification: They ensure the electronic device meets quality standards and works as intended, sometimes helping with certifications needed for different markets.

- Preparation for Mass Production: Once everything's set, they help streamline processes to make lots of the devices efficiently.

The market for outsourcing engineering companies is extensive and covers diverse industries, involving various project deliverables, including consumer electronics, robotics, telecommunications, medical devices, industrial systems, and automotive technology. These companies offer various technological capabilities and collaboration models tailored to fit specific project needs and industry requirements.

Why outsourcing electronics design is a smart choice - top 5 benefits

Businesses think about outsourcing electronic design for many good reasons. These reasons help make their projects better and more successful. Some undeniable benefits of outsourcing electronics design processes include:

- Focus on your core competencies

- Focus on your core competencies

Outsourcing your electronics design to a specialized company helps your business focus better on what it does best. By handing over the complexities of electronic design to experts, your business can direct its energy and resources toward what it does best. This shift in focus ensures that your efforts are dedicated to excelling in your own industry, while skilled professionals manage the difficulties of electronics design and product development. Emphasizing your core strengths not only boosts productivity but also fosters innovation and growth within your specialized field.

- Ensuring quality standards

- Ensuring quality standards

Partnering with a reputable electronic design company means entrusting your project to experts who prioritize quality. Often, companies opt for outsourcing because they recognize their limitations in meeting internal quality standards for electronics design.

These firms have established procedures and experienced professionals dedicated to upholding industry standards. They often have potent quality control measures in place, ensuring that the design process meets or exceeds the required benchmarks. By leveraging their expertise, businesses can rest assured that their electronics design will adhere to high-quality standards, fostering reliability and customer satisfaction in the final product.

Before you outsource electronic design, seek references from satisfied clients and review their portfolios to gauge relevant experience. Additionally, confirm the presence of a good quality assurance plan outlining how they'll meet your specific requirements.

- Bridging expertise and equipment gap

- Bridging expertise and equipment gap

Aside from letting you focus on your core competencies, when you outsource tasks like electronics design to specialized companies outside your own industry, you're essentially filling in those knowledge and skill spaces within your in-house team.

These expert companies and their own engineers bring a wealth of experience and technical know-how, allowing your business to tap into their specialized knowledge without needing to train or hire internally. It's like building a strong bridge between what you know and what you need to achieve, ensuring smoother operations and top-notch results in areas where you might lack expertise.

Outsourcing electronic design also grants access to advanced tools and equipment, particularly in the domain of embedded hardware. This means your project benefits from cutting-edge resources that might otherwise be costly to obtain or maintain in-house. Rather than investing in these tools and unfamiliar technology yourself, you can rely on the expertise of an electronic design service company equipped with specialized hardware and software. This partnership not only saves costs but also offers your own engineers the chance to collaborate with state-of-the-art equipment for hardware design. It speeds up project development by providing access to resources that enhance efficiency and precision in crafting electronic solutions.

- Reduced cost of manufacturing

- Reduced cost of manufacturing

Outsourcing electronics design can significantly cut down costs for your business. Electronic design service companies often operate more efficiently due to their specialized focus, meaning they can deliver high-quality work at a lower cost compared to handling it in-house. By leveraging their expertise, you avoid the expenses of hiring and training staff for unfamiliar technology and project management. Plus, these companies often have established relationships with suppliers, allowing them to procure materials at better rates, which translates to savings for your business. Ultimately, outsourcing electronic design can be a smart financial move that reduces overheads while ensuring top-notch results.

- Risk mitigation

- Risk mitigation

Risk mitigation becomes achievable through strategic measures like outsourcing the electronics design and relying on real-time operating system (RTOS). When a business outsources electronics design to specialized companies, it minimizes the risks associated with managing unfamiliar technologies in-house. These external partners are well-versed in cutting-edge RTOS and can navigate complexities efficiently. By leveraging their expertise, companies reduce the risk of errors or delays, ensuring smoother project execution and product development.

Wrap-Up

Choosing the right partner for electronics design is crucial for a smooth and successful project. Remember, it's essential to vet potential collaborators thoroughly. Look for expertise in real-time operating systems, a track record of successful project management, and a deep understanding of your industry's needs.

VECTOR BLUE HUB stands out as a reliable choice for electronics design, offering unparalleled expertise, proven project management skills, and a commitment to understanding your unique requirements. With the right partner like VECTOR BLUE HUB you can confidently scale through electronics design processes, ensuring a streamlined approach and successful outcomes for your projects.

Choose VECTOR BLUE HUB for a partnership that goes beyond expectations. Contact our experts!

Wojciech Jesionkowski

Wojciech leads the development team and strives to bring customers’ ideas to life. During his 14 years at VECTOR as an engineer, he has gained strong problem-solving skills and analytical thinking in product development. Privately, he's a father who loves to spend time with his family on shared outdoor activities and travels.