The Science of Electromechanical Assembly: Precision in the Modern Age

Have you ever wondered how many electromechanical products there are around us? Electric lights brighten our homes, flat-screen televisions entertain us, while power supplies and accessories transmit power to every electronic product we use. Get a glimpse into what it takes to create them, and how we can help you!

What is electromechanical assembly?

Electromechanical assembly, as the name suggests, is the process of combining electrical and mechanical elements to create new products – powered by electricity. In other words, they use electrical components to operate other machines.

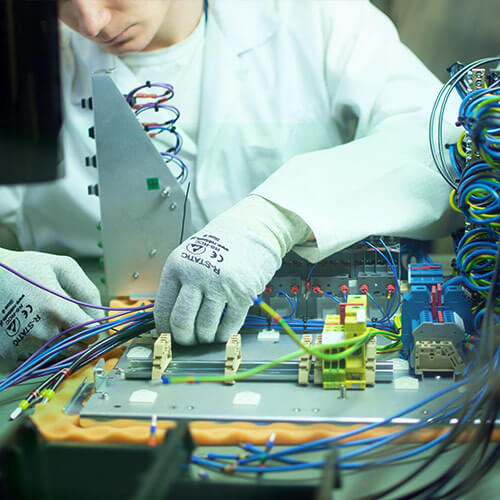

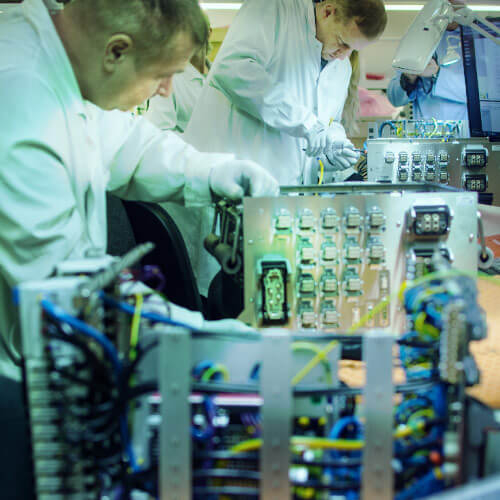

The first step in electromechanical assembly is constructing all the mechanical components in an appropriate configuration. This includes attaching any fasteners needed to connect other parts, and combining all the wires and cables necessary for everything to function properly. Once completed, it is time to add the other electrical and mechanical components. This is where a functioning system is created, by combining all the electrical and mechanical components.

One of the key benefits of an electromechanical assembly process is the ability to integrate multiple functions into a single unit. For example, a motorized door opener may combine an electric motor, gears and sensors to open and close the door automatically. This can save space and improve the overall efficiency of the system.

Manual or automatic?

The electromechanical assembly process begins

with the design and prototype phase, to determine the components required and the

overall layout of the system. Once the engineers have finalized the design, the

procurement department begins the journey toward sourcing the components needed

to assemble the final product.

There are several techniques used in electromechanical assembly processes based on manual operations. In contrast to automatic assembly, which often requires the large-scale integration of components, manual assembly is the leading, traditional method, involving the assembly of components using hand tools.

This involves automated assembly, where machines install integrated electronic circuits within single, standalone entities. A critical element in manual assembly is, therefore, the selection of suitable tools for the correct components and assembly operations.

"In a manual process, each step is performed by an operator, who has to assemble all the parts in a manner that does not require any computer-assisted steps, as opposed to automated processes which use vision systems to detect errors at each step. The proper selection of tools, clear instructions, and the right working environment guarantee the correct assembly and the highest quality. Whether the assembly process is more or less complex, or whether there is a need to assemble several electrical connections or many connected components, together with conducting the essential tests to ensure the highest quality and reliability, we have the experience to support our customers", added Jarosław Krzyżanowski.

Therefore, if you are seeking the reasoning behind the superiority of automatic over manual assembly, we do not want to disappoint you. It would be a mistake to recommend one choice without knowing the product architecture and the objectives. This stage should be preceded by an analysis of the documentation, the intended use, and your needs. The advantage of manual assembly is particularly visible when we are able to react quickly to emerging issues. This is possible by modifying the process, assembly tools, or production environment. The cost-effectiveness is unequivocal when we reduce the cost of a quality problem. The latter enables experienced engineers to solve problems quickly and to improve the process by increasing quality.

Quality Assurance in Product Assembly

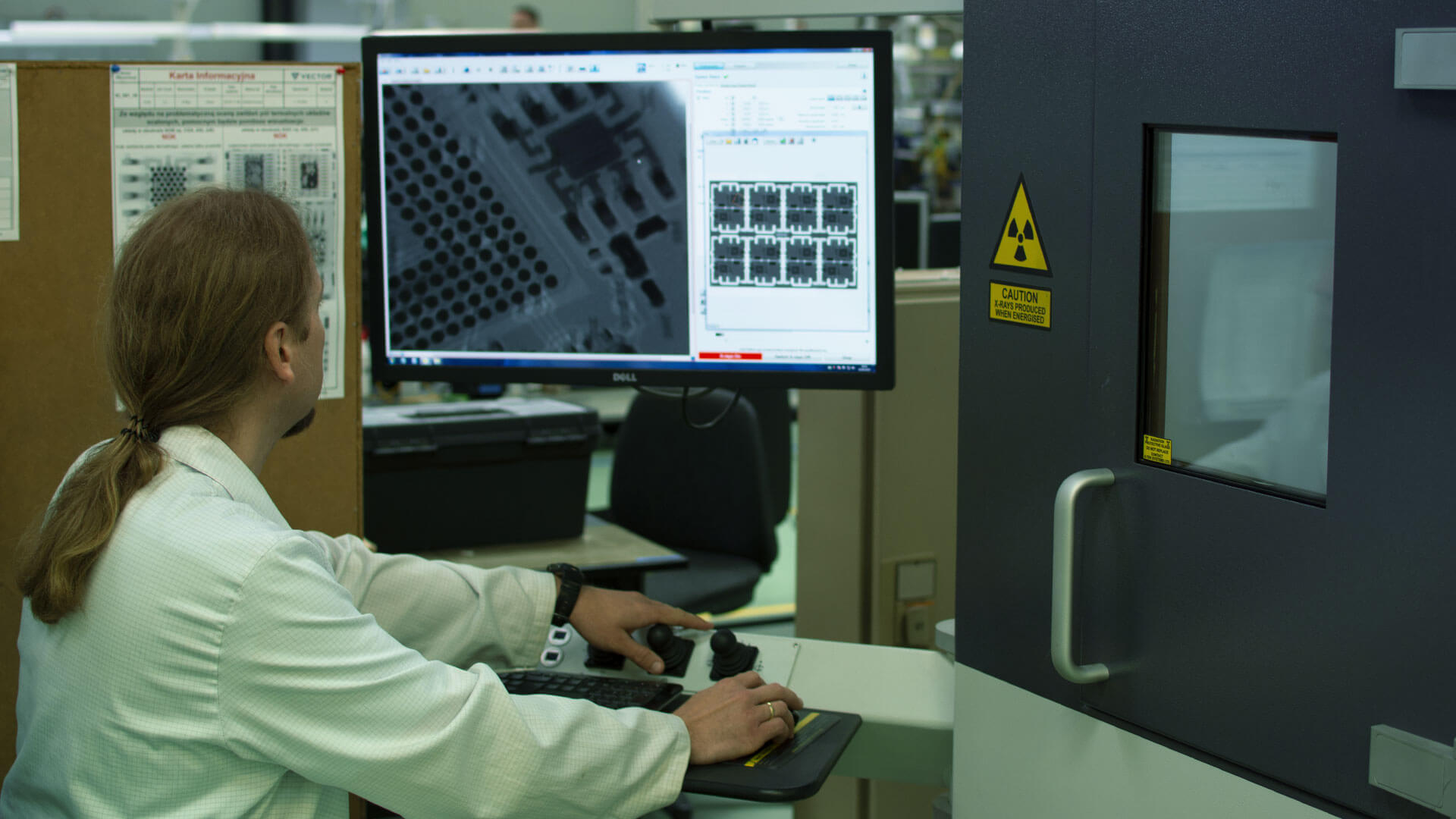

Quality control is an essential aspect of electromechanical assembly, as the inspections and testing are conducted throughout the assembly process to ensure that the final product meets the required specifications.

These may include:

- visual inspections,

- functional testing,

- measurement of electrical characteristics.

In recent years, there has been increasing demand for electromechanical assemblies that are smaller, faster, and more energy-efficient. As a result of technological advancements, such as the introduction of micro-electromechanical systems (MEMS), it is now possible to develop more sophisticated and capable assemblies working in extreme environments, such as the automotive or aerospace industries.

What must you deliver to an EMS partner to begin your Electromechanical Assembly project?

Mechanical Drawings

The mechanical drawings are the blueprint for your entire project. They show all the holes, slots, and other features that need to be milled out of the material. They also show where to locate all the components to install them correctly.

BOM – Bill of Materials

A BOM is a list of all the parts needed for an assembly project, along with the part numbers and quantities required for each component. For example: if you have an electromechanical assembly project that uses five different bolts, each with a different size and threading pattern, then each bolt would have its line item in your BOM, listing all its specifications along with how many are required and where they go in your assembly process.

Test Protocols

These documents outline how engineers test each component after the manufacturer installs it. The test protocols include instructions for testing each component and instructions for ensuring that all the components work together as a whole unit.

Wire Run List

The wire run list is a document that outlines how all the wires are connected between different components - the power and data connections between all the electronic and mechanical components. Without a wire run list, it's impossible to know how everything should be connected for the product to work correctly.

Acceptance Criteria

What criteria must be met before you can accept an assembled part? For example, if you are assembling an electronic component, should all the elements be connected properly with no loose connections?

Golden Sample

As with any other type of manufacturing, it is important to provide the contract manufacturer with a "golden sample" — a fully functional unit that you can use as a benchmark for the other units being produced by your manufacturer. This helps to ensure that each unit meets the quality standards throughout the manufacturing process. This should include everything, from the outer casing to installing all the internal components.

How we can help with Box Build and Electro Mechanical Assemblies

Finding your way through a tangle of wires can be difficult, but not for our experienced assembly specialists. At VECTOR BLUE HUB we have in-house experience involving box builds and electromechanical assemblies.

Electromechanical assemblies:

- Switch panels and switch assemblies - electronic switches, circuit breakers, and control system panels

- Sensor wires and speed sensors - including high-voltage and high-current circuits with testing

- Power supplies and power boxes - coils, busbars, fuses, and circuit protection assemblies

- Cable assemblies and harness assemblies - in-house for low volumes, dedicated cable manufacturer for high volumes, with cable marking and wiring integration

- Sensing elements - control systems using electrical signals

- Pneumatic and hydraulic assemblies - pipes, valves, sensors, and leak testing

Get a free consultation for your next electromechanical assembly project to achieve maximum efficiency!

Electromechanical assembly has been our core business and area of expertise for more than two decades. During that time, we have established a solid reputation as the go-to source for precision craftsmanship, prompt delivery, and high-quality components. Whether it is the electro-mechanical assembly of a complex telecommunication element or a power enhanced mechanical task, we offer the same level of quality in all the assembly methods used to construct these products.