How do you profit when your manufacturer sticks to a process?

Recently, we went through the subject of working along with the process in companies. It is very wise of an entrepreneur to set the work in procedures (we know that now), but is it wise from the client's perspective to track down paragraphs? Let us keep an eye on what information clients get when they know their services provider sticks to process stages.

In the previous article we compared process to a map — which gives not unlike functions than

those a process does. So now let us imagine that we follow a path after the

person who carries its topography in mind. For some reason, we are made to

continue our journey on our own. What now if we were never given a map? We find

ourselves pretty lost, which shows otherwise if all is written down — where to

turn, to whom to go and where is our place. With a map the project is monitored

and executed according to an agreed schedule. What a client receives, however,

knowing we have such a map, is that their investment is well managed.

But before the pecuniary

advantage comes, there rises something far more precious, which we all chase

when doing business.

Process cushions business

The phrase most true in

the manufacturing sector. When it comes to electronic devices manufacturing,

though, right by 'thank you' and 'sorry' stands the third magical word, which

is: 'reliability'. That entails repeatability which is guaranteed only when we

are sure that in case of emergency the company we work with knows what to do.

Figuring the problem out is the last thing any client would like to hear when,

for example, the purchasing of components occurred to be fallible — out of

unpredictable causes, like: weather, factory fire, political crises, etc. A

simple thing, but if the procedure enables us to make a smooth turn to an alternative supplier, the case might never

be heard of for the client.

Security is everything

here.

"Given that our development projects are based on time-and-material agreements," says Joanna Marzec, Value Chain Director at VECTOR BLUE HUB, "when the client pays straightforward for the hours spent on their project, they want to skip the risk of prolonging those hours by pure randomness of events. This can be prevented by nothing but a process."

Then we can say that the

role of the process for the client is to give them safety of investment.

Another key thing, ensuring customer safety, is certainty that the

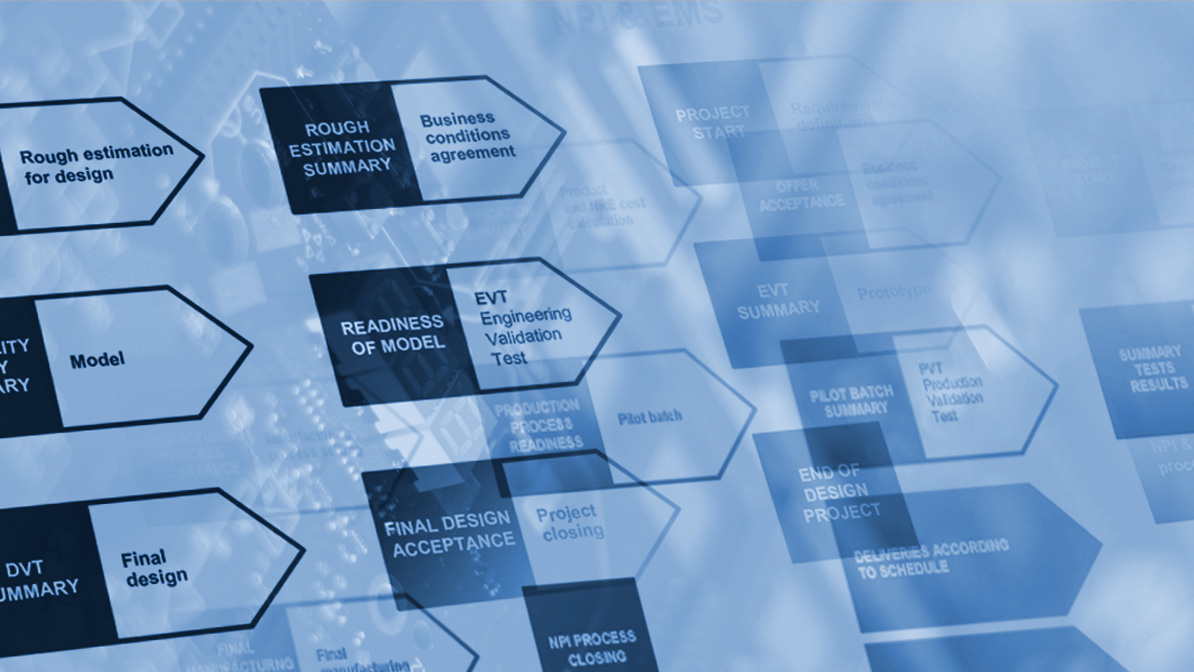

final product will be delivered on time, compliant and on cost. The above is protected by milestones of the

process, regulates its flow allowing for the client to control and audit what

is going on inside their projects. This kind of transparency builds trust in

business.

Process repays in time and money

To both of the sides:

client and producer. Each side dreams about nothing but the optimal scenario

for the project to unfold and finish. Financial advantage comes as the

consequential part of the whole planning.

A process works for:

- strengthening the

relationships with stakeholders through reliability

- better management of

resources and its utilization

- measurement of the

work done

- improving work

efficiency

The client should be

enabled to peep into each of the points above. Based on our 30 years of

production experience, when the process of manufacturing already counted many

turnarounds, we made it to collect the portfolio of: suppliers, cooperative

labs, universities and other clients. These are the partnerships born out of

the system of work.

Moreover, throughout the

cycles, we know that the realization needs a specific amount of material and

time to finish the upcoming project. Then again, the company with years of

production experience, after all turnarounds,

gages exactly the necessary input and

reduce costs; experience, thus, results in the competitive pricing.

Work flow control ends

up with space for improving. If the client meets a company with a process, they

receive the simple message saying: That is a learning organization. A company

develops because it measures, and after every turnaround it becomes smarter,

agiler and more experienced.

"Even if a process entails changes, and we hate changes, it brings profits in the end. It says to the people who want to do business with us that we have stepped on this path so many times that little might surprise us. That's a pretty saying to get from a manufacturer, isn't it?" says Joanna.

We introduce you to learn more about the processes we work with in the contract manufacturing services section of our website.