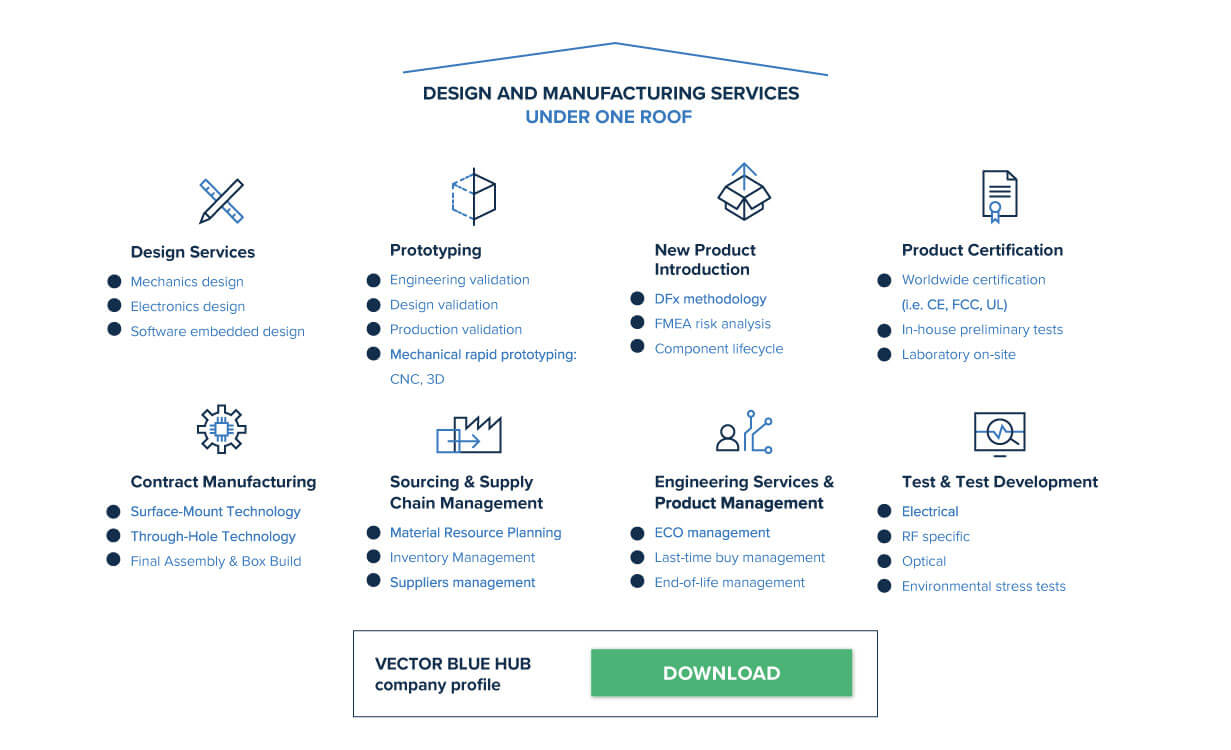

Electronic Manufacturing Services - design and mass production under one roof

The ability to respond with services that deliver real value to the customer and invest their money wisely is today the most important aspect of Electronic Manufacturing Services. Keeping electronic design and manufacturing under one roof represents the smart approach, one where the customer benefits by being served better, faster and more cost-effectively.

Design and manufacturing under one roof - a concept explained

Simply put, the under one roof concept in electronics manufacturing ensures that all services are managed internally, in one place. The journey that the mass market product must make is often split between design houses, those specializing mainly in the productization of ideas or traditional EMS companies that offer NPI and volume production. There are very few companies that can provide a comprehensive range of design and manufacturing services.

As we all know, partners play an essential role in maintaining the continuity of supplies and pricing at the agreed levels. This is especially crucial in such industries as the military, health, insurance and ecology. However, this can sometimes be a challenge to achieve, considering the availability of components and shipping. Often the issue is not about the risks related to material quality, but the measurement of risks that may increase the total cost of ownership. A company with experience in hardware design and manufacturing can quickly and efficiently resolve this kind of problem.

Electronic hardware design

The design of electronic devices requires extensive knowledge and vast experience. It begins with complex standards, high-speed signal integrity and complex RF signal characteristics. Once the base requirements are defined, concepts can be created to meet the user’s requirements. One method of conceptual thinking is sketching, which helps to set free even the most abstract of ideas – at a glance. Once the sketches are produced, the idea can develop and be experimented on in many different ways. The larger the number of concepts developed, the better the product ideas will be.

Once the main assumptions are in place and we are comfortable with the direction we have chosen for the hardware design, the next step is to develop the embedded software and then move on to the mechanical designs and thermal management.

“Together with the team, we gather all the required product features, concluding it with the Product Requirement Document. The Product Owners and the engineering team do not have an easy job: they must take into account temperature ranges, the user interface, electrical parameters, EMC, weather sealing, safety and many other requirements. A completed Product Requirement Document allows us to move to the second phase: prototyping and market tests to validate the customer’s idea and prepare it for mass manufacturing,” said Wojciech Jesionkowski, Hardware Engineering Manager.

New Product Introduction (NPI) process in a hardware design

Simultaneously with the prototyping, the new product introduction phase starts by preparing the electronic device for mass manufacturing. This process involves cooperation between not only the R&D and manufacturing engineering teams but also the product lines and supply chain partners that are required to design, develop, test, manufacture and ship the electronic device.

The final stage is manufacturing. Having received the guidelines from the construction department, the production managers establish the main standards and resources required to begin production. Depending on the client’s requirements, the EMS provider can arrange low- and medium-volume manufacturing. However, if the first phases of the hardware design and prototyping are not managed well, the electronic device will not be sufficiently well prepared for manufacturing. The holistic approach, which keeps design and manufacturing in one place, can significantly shorten the time to deploy an electronic device in the market.

“At VECTOR BLUE HUB, we strive for excellence from the very beginning, long before the product is considered for manufacture. That’s why we follow Design for X – we can address issues at an early stage, especially for NPI and mass manufacturing. I strongly believe that the design team that lacks a complete understanding of the fundamental procedures and limitations on the manufacturing side may develop a product that simply cannot be manufactured. Keeping the manufacturing and design services under one roof represents the smart approach, removing the space for communication gaps. As a result, we are able to develop the right product, at the right time and the right cost,” added Wojtek.

How can you benefit from hardware design and manufacturing services under one roof?

There are many advantages accruing from selecting an Electronic Manufacturing Services company that maintains all its business's services under one roof. First and foremost, you save both time and money. It's also more convenient to manage the entire project with just one partner.

Advantages of the hardware design and mass manufacturing under one roof approach:

- Easy to manage - you are safe to focus on your core business, while an EMS partner takes good care of everything else.

- Less capital investment - you don't need to develop your manufacturing or R&D centre, or invest in training and retaining employees.

- Manufacturing scalability - if there is a need for larger volumes, you can quickly extend your production capacity.

- Quick Time To Market (TTM) – since selected phases overlap, the design and volume production times are shortened.

- One-stop shop - your EMS provider supports certification of your product because it is essential to ensure that the quality complies with international standards and any safety regulations.

Our electronic hardware design

The mission to bring a final product to life can be very challenging. This is especially true when the story is continuously variable, driving the need to adjust the electronic design and manufacturing processes to suit the complexity of the customer’s product. At VECTOR BLUE HUB we can face up to this task - and not just as a manufacturer or design house. We are ready for all challenges in being your close partner in design and manufacturing services for electronic devices.

We believe that the under one roof concept, which we represent, ensures we can achieve the highest agility in our everyday work. Thanks to our holistic approach we can support our customers at every stage of the project: from the productization of concepts through prototyping, new product introduction (NPI) to mass manufacturing. You can safely focus on further developing your business while we take good care of everything else.

Our tech-savvy engineers have extensive knowledge and experience in the fields of mechanics, electronics and software design. It is the combination of all these three elements that enables a smooth-running development process. Therefore if you are seeking an easy-to-do-business-with design partner, request a free consultation today!