Collaborative Product Launch Planning with Your EMS Partner

The new product introduction process always carries many potential risks. A successful concept phase preceding the development stage is crucial because implementing changes with the design process underway can be expensive and time-consuming.

When planning a successful product launch for your target audience, things that look perfect on a blueprint often cause bottlenecks in manufacturing.

How can you avoid costly issues and so accelerate product time to market?

Find out in our article in which we unleash the power of collaborative product launch planning with an EMS partner!

Table of Contents

- What is a product launch plan?

- What should a product launch plan include?

- What is a new product launch checklist or template?

- Who is involved in launching a new product?

- Benefits of Collaborative Product Launch Planning with an EMS Partner

- How to Choose the Right EMS Partner for a Collaborative Product Launch

What is a product launch plan?

A product launch plan is an orchestrated protocol describing the method of launching a new commodity on the market.

This strategic blueprint encompasses an array of various activities, ranging from product ideation and validation, through rigorous market analysis, to the creation of an incisive marketing and communication strategy. The quintessence of this plan is to optimise manufacturing efficacy, minimise potential hazards, and secure a formidable market foothold for the freshly minted electronic product.

The product launch plan harmonises seamlessly with the client’s business aspirations and target audience, aiding them in cementing their position within their desired market segment.

What should a product launch plan include?

An electronic product launch plan should incorporate several key elements:

1. Product Definition and Specifications

This phase should include a detailed description of the product, its specifications, functionalities, unique selling points, and the problems it solves.

2. Market Research

A deep understanding of the target audience, competition, and market trends is crucial. It helps tailor the product and the marketing strategy to meet customers’ needs and expectations.

3. Prototyping and Testing

Before full-scale production, the design and functionality of the product should be validated through prototyping and rigorous testing. This ensures the product meets the required standards and performs optimally.

4. Supply Chain Management

A comprehensive overview of the production timeline, supply chain logistics, and inventory management must be part of the plan.

5. Pricing Strategy

Pricing should be determined by taking into account production costs, competitors’ pricing, perceived product value, and what the target customers are willing to pay.

6. Marketing and Sales Strategy

An effective marketing strategy, which includes branding, advertising, and sales tactics, must be designed to generate awareness, interest, and purchase intent.

7. Post-Launch Support

This involves planning for customer service, warranties, and product updates. Maintaining a strong relationship with customers post-launch can lead to customer loyalty and future sales.

8. Performance Metrics

Set clear and measurable goals for the product launch. It could be in terms of sales volume, market share, or customer satisfaction. Periodic evaluation helps in adjusting the strategies to achieve optimal results.

What is a new product launch checklist or template?

A new product launch checklist or template is a structured guide that helps to ensure that all the necessary steps are taken during the product launch process. It includes a variety of tasks ranging from product development to marketing strategies, which are crucial for a successful product introduction into the market.

Here are some online resources that offer templates or checklists for a new product launch:

- HubSpot’s Ultimate Product Launch Checklist – HubSpot provides a comprehensive checklist that includes competitive analysis, an overview of the market analysis, and a detailed project strategy.

- TrewMarketing Smart Product Launches for Engineers – This guide is written specifically for the business owner, product manager, and marketing leader preparing to launch a product targeted to technical audiences in the B2B space.

- Plaky’s Guide to a Successful Product Launch – A comprehensive resource designed to equip you with the strategic knowledge and practical tools necessary for an effective product introduction.

Remember that these checklists and templates should be adapted to suit your specific product, company, and market needs.

Who is involved in launching a new product?

Introducing a novel electronic product demands a multi-disciplinary approach, engaging a myriad of key stakeholders. At the epicentre are the Original Equipment Manufacturers (OEMs), the visionaries behind the product concept and its developmental oversight.

On the other hand, the Electronic Manufacturing Services (EMS) providers are crucial in bringing new products to life, transmuting the design into a concrete product by steering the manufacturing, testing, and occasionally distribution phases.

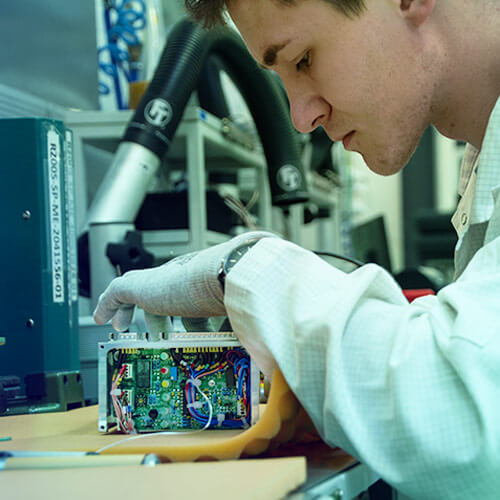

EMS partner engineers and designers are responsible for ensuring alignment between the product and the OEM’s specifications and addressing market demands.

Supply chain managers orchestrate the punctual and cost-effective acquisition of components, while quality assurance teams labour diligently to uphold stringent quality benchmarks.

OEM’s marketing and sales teams are indispensable in market positioning and customer engagement. Their task is to generate market awareness and stimulate sales. Lastly, customer service teams play a vital role in the post-sale phase, bolstering customer satisfaction and fostering loyalty.

Benefits of Collaborative Product Launch Planning with an EMS Partner

As mentioned above, the EMS company is vital in introducing new products to the mass market. It serves as a technology hub, bridging the chasm between the product idea with its specification and the ability to manufacture the desired solution.

Endowed with a seasoned partner adept in both the art of design and the craft of fabrication, the intricate science of bringing the product to life becomes more manageable and more cost-effective.

What more can you gain by choosing an experienced EMS partner?

A. Optimised Design for Manufacturing

Design for Manufacturing (DFM) is a fundamental cornerstone in the successful launch of any product. Its importance lies in its ability to minimise production complexities and potential pitfalls, effectively leading to reduced manufacturing costs and time to market.

A product designed with manufacturing in mind is not only more straightforward to produce but also stands a better chance at market success, making DFM an invaluable strategy in product development.

Ideally, Design for Manufacturing (DFM) consultation should take place early in the design stage, long before the product starts to be manufactured. Therefore, the more you fine tune this phase, the better the results you can get in assuring that the design is well-optimised and does not include unnecessary costs.

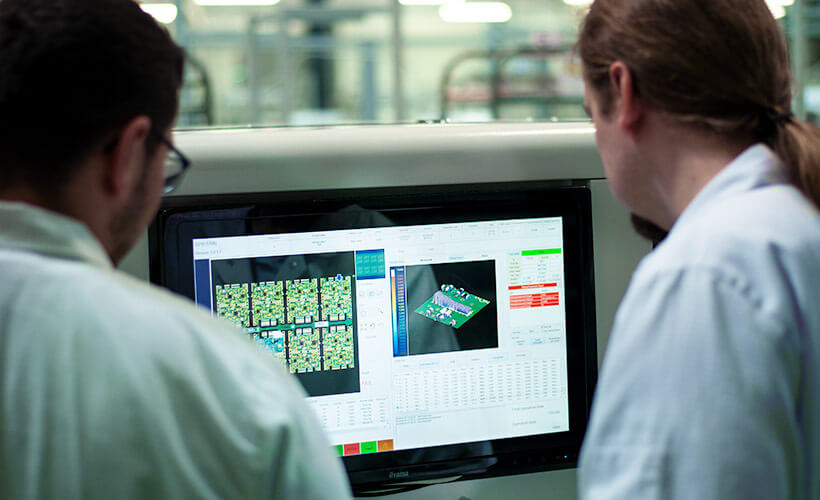

Moreover, a properly executed DFM process involves a team of designers, Printed Circuit Board Assembly (PCBA) engineers, technologists, and sourcing and supply chain representatives. The latter are currently the most desirable for consultation, considering the current raw materials shortages and component lead times.

B. Risk Mitigation in Product Development and Launch

Staying up-to-date with your EMS partner with an efficient supply chain management process, observing deviations and guiding you into best practices, allows you to easily implement a preventative plan to ensure that deadlines are met.

As a result, you will mitigate this risk and identify crucial points in the product’s roadmap to gain a competitive advantage.

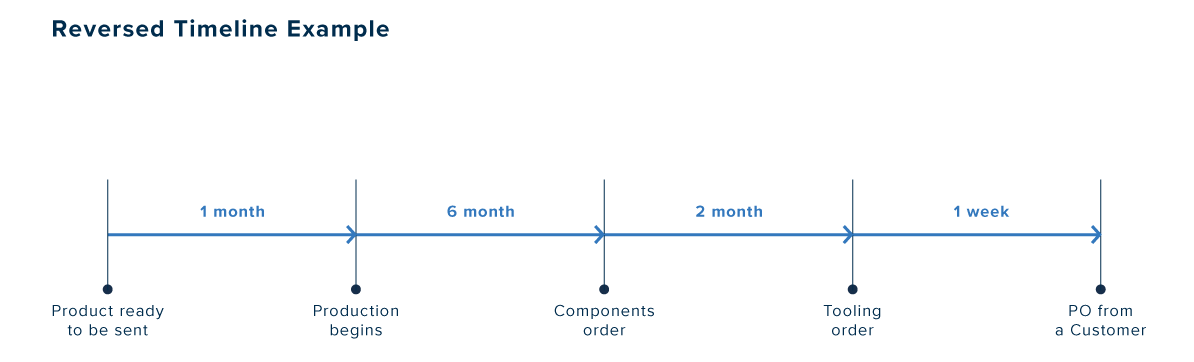

An experienced EMS partner can also serve you with advice on preparing a reversed timeline. You present the proposed product launch date, and in response, you receive a plan with a reverse chronology. The aim is to define all the milestones with realistic time frames, as determined by a manufacturer that is fully aware that the first prototype coming off the assembly line isn’t the last. Counting backwards creates a production timeline that works, taking into account the time needed to pass all the gates.

C. Access to Specialised Expertise and Resources

Working in collaboration with an experienced EMS partner brings you closer to a wealth of specialised expertise and resources; elements that may not be readily accessible within your own organisation.

These partners can leverage their rich experience, cutting-edge technological insights, and deep industry connections to facilitate every stage of your product’s life cycle. They are equipped with advanced production machinery, skilled technicians, and effective quality control processes to ensure the product aligns with your specifications and quality standards. From the initial concept to final production, an EMS partner offers a comprehensive suite of resources, allowing you to focus on your core competencies while they handle the complexities of manufacturing.

It’s not just about getting the job done, but about getting it done right, with expertise and resources that can elevate your product to new heights.

How to Choose the Right EMS Partner for a Collaborative Product Launch

When considering potential EMS partners, it’s vital to dig into their level of experience. Remember, the more you know about your potential partner, the better equipped you’ll be to make an informed decision.

This isn’t just about checking boxes; it’s about creating a successful, collaborative relationship for your product’s future.

Don’t shy away from the hard questions – they’ll lead you to the best fit.

Questions to Ask When Selecting an EMS Provider:

- Is the potential EMS capable of producing the required product volume?

- Does the EMS partner have a sourcing and engineering team in its organisational structure?

- Does the electronic manufacturing company have the knowledge and technical infrastructure to validate and test your product?

- Does the EMS partner take care of the logistic aspect to deliver your order to any place, e.g. directly to the end customer?

- Does the company have sufficient experience in design or/and manufacturing in your industry?

- What is the Minimal Order Quantity (MOQ) your EMS partner might be potentially interested in?

- Does your EMS partner work on consigned material?

- Where is the manufacturing plant located?

Transparent communication — a fundamental requirement

Don't hold back in asking us anything at VECTOR BLUE HUB. We stand by the importance of clear communication and bespoke solutions, offering our unwavering support to bring your ideas to life. Ensuring a harmonious partnership and successful production is at the heart of our dedication.

Initiate your journey of innovation today by connecting with us!