Design of hardened devices for harsh conditions. Crafting resilience with VECTOR BLUE HUB

In today's dynamic technological landscape, devices have seamlessly woven themselves into the fabric of our daily lives, from urban comforts to the challenging fringes of our world. As society advances in search of new solutions for growing needs, there is also an increasing demand for resiliently designed, intelligent equipment in the telecommunications sector, across various fields of its application. As we push through this technological era, the hardening and reliability of these devices in harsh conditions become paramount.

At VECTOR BLUE HUB, we bring to the table our experience in system hardening standards and implementing market-ready industrial telecommunication devices tailored specifically for these demanding situations. This article sheds light on our approaches, best practices, and the methodologies we employ to guarantee that our devices not only last but consistently deliver optimal performance under challenging circumstances.

Table of Contents

- Navigating tech terrain: mastering resilience in extreme environments

- Importance of durable electronic design across various sectors

- Robust design fundamentals. Understanding the principles of designing for extreme conditions is the bedrock of creating devices that surpass expectations.

- VECTOR BLUE HUB - Your partner in designing resilient devices

Navigating tech terrain: mastering resilience in extreme environments

In an era marked by rapid technological progression, the concept of system hardening takes center stage. Before diving into the art and science of building ultra-resilient devices for severe conditions, we must first grasp why resilience is paramount in modern tech:

-

Diverse deployment: devices today find themselves in a myriad of challenging terrains, from the icy landscapes of the Arctic to the blistering heat of deserts, demanding robust operating system hardening.

-

Array of challenges: such environments pose threats of extreme temperatures, intense humidity, and heightened physical pressures, often leading to device dysfunction. This underscores the

importance of comprehensive devices and systems hardening.

-

Real-world implications:

failures can wreak havoc

on productivity and result in considerable financial and operational setbacks

in sectors as diverse as energy, transportation, defense and outdoor

adventures, underscoring the need for continued efforts in standards to

strengthen the individual devices that make up the entire system.

- More than a trend: prioritizing extreme environment electronic design is less about chasing a trend and more about addressing a critical need. As an example in telecommuncation systems: involving securing against potential attack surfaces and ensuring internet security through measures like multi-factor authentication and restricting access to sensitive systems.

Grasping the weight of these considerations sets the stage for our journey into the realms of best practices for designing hard-wearing devices meant for the world's harshest conditions.

Importance of durable electronic design across various sectors

In the realm of manufacturing, industrial settings, the functionality and reliability of electronic, operating and computer systems are paramount. Machinery, sensors, and other critical components often operate under demanding conditions. These conditions are especially prevalent in extreme environments characterized by extreme temperatures, high humidity, and exposure to dust and chemicals. Given these extreme challenges, there's a rising dependency on electronics specifically designed for extreme environments, ensuring optimal performance even under these severe conditions. By embracing extreme environment electronic design principles, these systems surpass the performance benchmarks set by conventional electronic devices.

Ensuring the robustness and seamless

functionality of these devices in extreme conditions is vital to guaranteeing

continuous production, significantly reducing potential downtime, and in the

grand scheme, leading to substantial cost savings. This focus includes

electronics hardening, firmware and software application hardening to protect

against data breaches and intrusion prevention, as well as system hardening

standards for critical infrastructure.

Telecommunications and IoT:

Standing at the forefront of this demand is the telecommunication industry. With the rapid expansion of the Internet of Things (IoT) and the essential nature of uninterrupted communication, sectors such as intercom systems, satellite communications, and mobile networking demand devices of unparalleled resilience. Given the centrality of communication in today's world, ensuring these devices can weather extreme conditions is not just a priority—it's an absolute imperative. At VECTOR BLUE HUB, we have extensive experience in creating devices adapted to harsh conditions. Our advanced solutions include passive and if needed active cooling systems which protect devices against environmental conditions, and security systems that safeguard access at the firmware and software level.

What other areas require devices built to withstand challenging weather conditions?

- Industrial Automation:

Delving

into the manufacturing domain, we encounter machines and sensors operating

round-the-clock, often in harsh conditions that challenge conventional

electronics. Factors like chemical exposure, dust, and even extreme temperature

variations necessitate devices with robust design, ensuring consistent

production and influencing significant cost savings.

- Military and Defense:

High

stakes and challenging environments define this sector. From arid deserts to

the icy expanses of the poles, military operations need equipment that's more

than just reliable; they need the robust. Communications, surveillance, and

mission-critical systems must withstand these extremities without a hitch.

- Outdoor Consumer Gadgets:

For

the modern adventurer, resilience is as essential as functionality. Whether

it's tools for hiking or equipment for extreme sports, outdoor gadgets must

withstand nature's myriad challenges. In this realm, a brand's commitment to

quality is often reflected in the durability of its products. This approach

often includes ongoing assessments and adherence to system hardening standards

to ensure gadgets are capable of handling harsh conditions without compromise.

Robust design fundamentals. Understanding the principles of designing for extreme conditions is the bedrock of creating devices that surpass expectations.

Creating

devices suited for extreme environments demands a deep dive into both the

theoretical and practical aspects of electrical and computer engineering.

Unlike conventional electronic devices, extreme environment electronics are

crafted specifically to face the harshest conditions. Understanding the

principles of extreme environment electronic design is crucial. By focusing on

these core principles, designers can ensure the longevity, performance, and

resilience of devices in even the most challenging settings.

Designing telecommunication and IoT devices that

can thrive in extreme environments requires a more profound grasp of both

electrical and computer engineering than only a basic background. Unlike

standard electronic systems, extreme environment electronics, a field of study

where extreme environment electronics explains the intricacies of designs

tailored for harsh conditions, stands at the forefront. By incorporating the

principles of environment electronics, telecommunication devices are not only

ensured seamless connectivity but also guarantee device longevity and

resilience in the most demanding of scenarios.

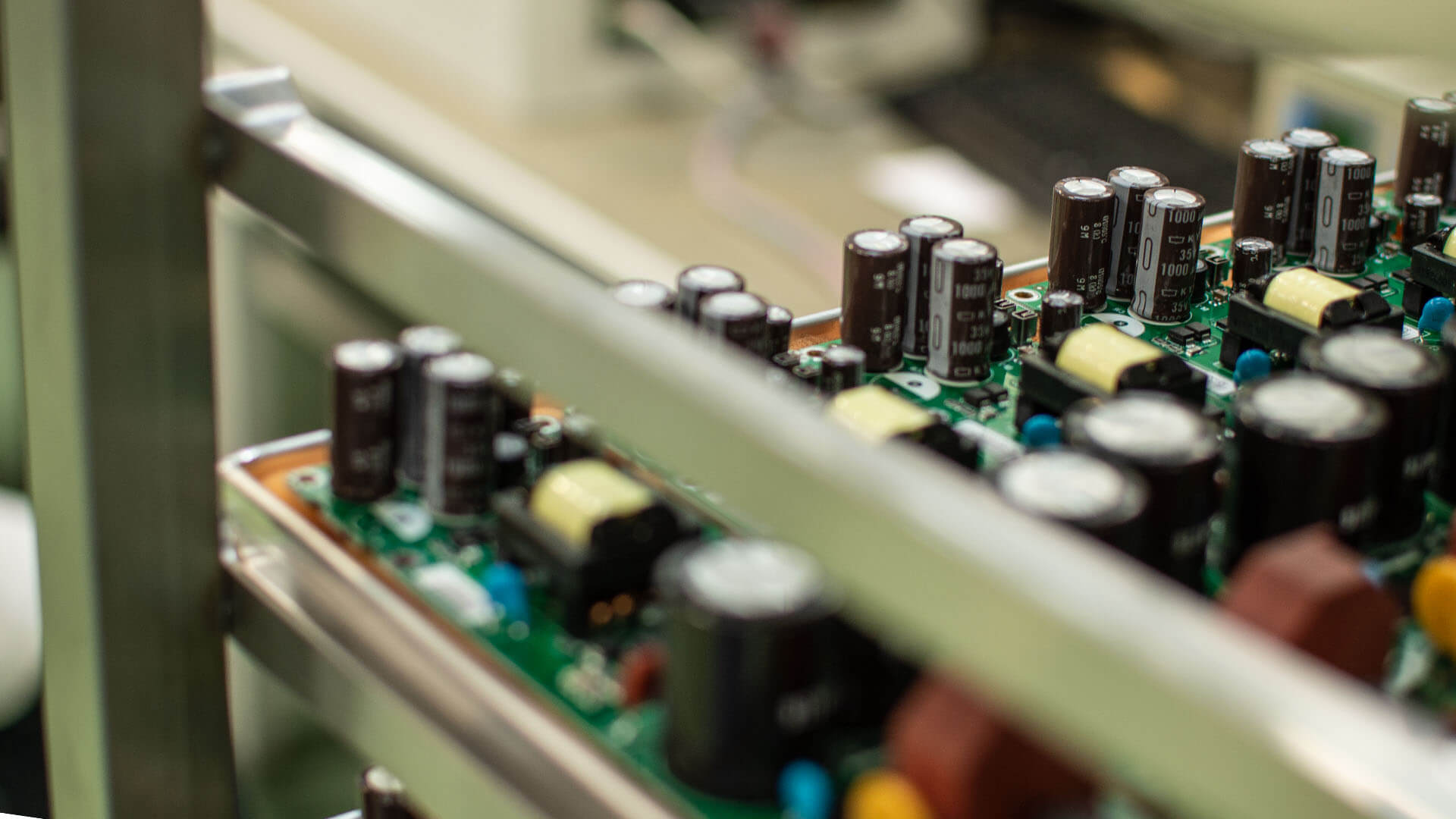

Materials and Construction for Telecommunications and IoT

The

foundation of resilient telecommunication and IoT devices is rooted in the

selection of suitable semiconductor technologies, pivotal for environment

electronics. Beyond just durable plastics or corrosion-resistant metals, it's

about embracing the realm approprate

semiconductors electronics units and other tailored technologies. These

devices are designed to be immune to challenges like humidity, corrosive

environments, and even electromagnetic interference - concerns prevalent in the

telecommunication spectrum. Electronic systems intended for such rigorous

demands safeguard the device's core functionalities, ensuring seamless

communication even when faced with conditions that would hinder ordinary

devices.

Sealing and Protection in Communication Devices

When

it comes to extreme environment electronics, especially in the

telecommunication sector, shielding against external threats like moisture,

dust, and electromagnetic interference is non-negotiable. Such devices should

not just meet but exceed the highest IP (Ingress Protection) class. Using

gaskets, seals, and specialized coatings, all integral to environment

electronics, ensures the device's integrity, reliability and signal quality.

Temperature Adaptability in Telecommunications

Telecommunication and IoT devices destined for extreme environments represent a challenge, especially when considering temperature variances. These devices, often linked with energy and space exploration endeavors, need components resilient to both high and low temperature environments. Efficient thermal management, encompassing heat dissipation strategies and advanced cooling solutions, is essential. These considerations, combined with the intricacies of analog circuits operating under such conditions, ensure that communication channels remain open and uncompromised. This necessitates continuous effort in maintaining operational security and adhering to system hardening standards.

Shock and Vibration Resilience in IoT Devices

In

the vast IoT landscape, resilience against shocks and vibrations is crucial,

particularly when devices are near heavy machinery or areas of high mechanical

stress. By integrating effective mounting solutions and shock-absorbing

materials, these IoT devices, designed for extreme environments, ensure data

integrity and stable connection. This is especially important in maintaining

operational security and protecting sensitive and crucial information under

harsh conditions.

Power Management in Telecommunications

In

the telecommunication sector, where devices often communicate over vast long

period, distances, power efficiency is paramount. The adoption of

energy-efficient semiconductor solutions, alongside optimized firmware and

smart power modulation techniques, is indispensable. This approach is integral

not just for prolonging the device's operational life but also for ensuring

consistent signal strength and data transfer rates, critical in operating IOT

systems.

Environmental Testing and Device Verification

Comprehensive environmental testing is essential for any device intended for extreme environments. This includes temperature cycling, humidity tests, shock and vibration testing, and modeling radiation effects. Real-world simulations, coupled with reliability estimation and verification techniques, form the cornerstone of this process. Such rigorous testing ensures devices stand up to challenging conditions, guided by system hardening standards, ongoing assessment, and regular assessments. This thorough approach aims to lower risk and ensure devices adhere to industry standards, reinforcing their resilience and reliability.

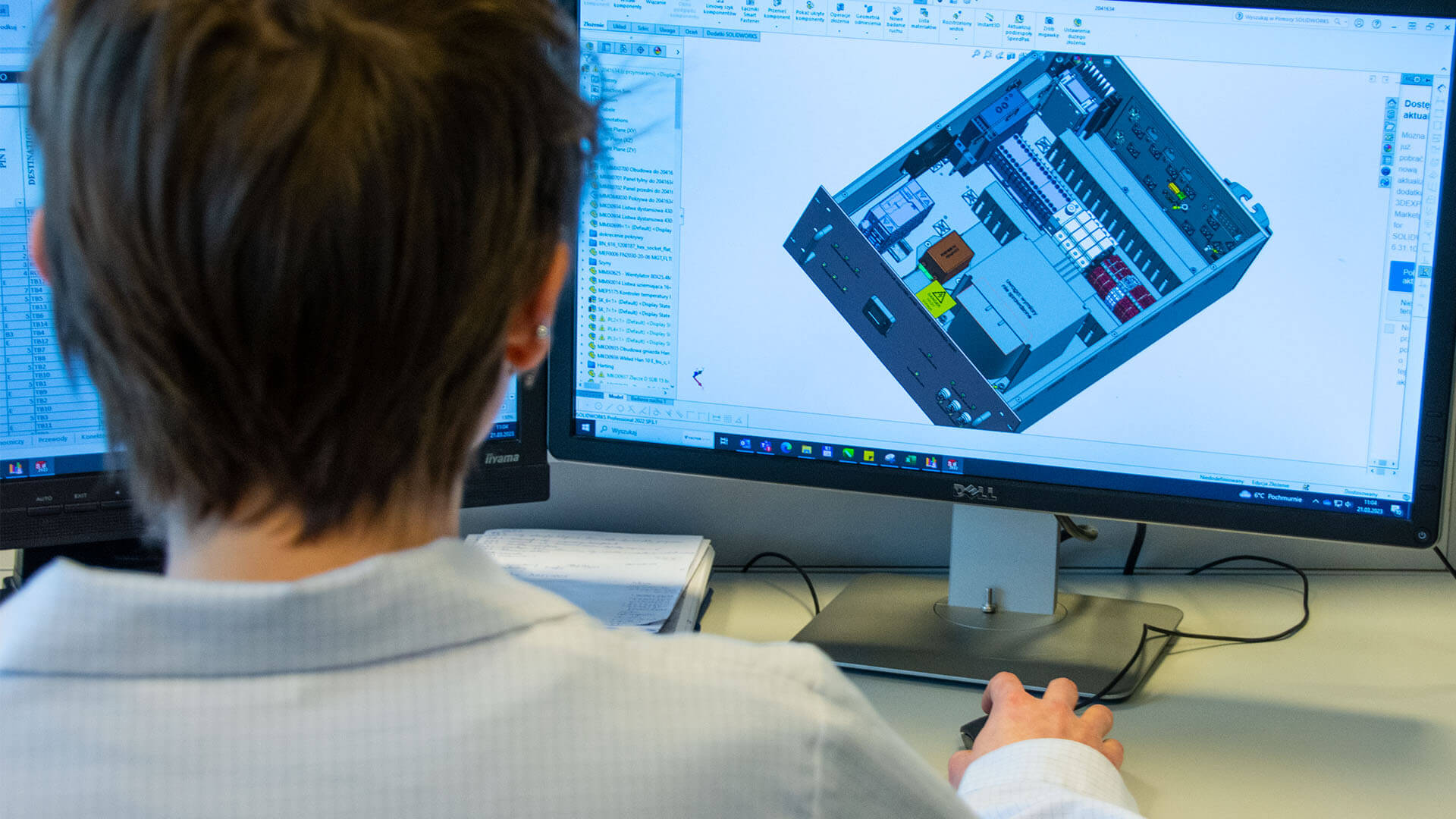

VECTOR BLUE HUB - Your partner in designing resilient devices

At VECTOR BLUE HUB, our approach to high temperature resilience leans on passive cooling, though we also have expertise in active cooling via fans. Tackling low temperatures often requires innovative solutions, such as using additional electronics to heat certain components to operational levels. We've mastered designing devices that can withstand up to 95% humidity and are corrosion-resistant through the judicious selection of materials and rigorous verification tests.

Moreover, our devices adhere to an IP67 rating, ensuring dustproof and water-resistant capabilities, and are built to endure vibrations during both transport and operation. The security of our IoT devices against hacking is fortified with hardware-based key protection. Furthermore, these IoT devices are power-efficient due to optimized software and hardware design. We've also tackled the challenge of vandalism, crafting devices such as vandal-resistant intercoms. Importantly, we prioritize longevity in these challenging environments. At VECTOR BLUE HUB, this is achieved through comprehensive construction analysis (e.g., MTBF calculations, lifetime of key components) and reliability tests (HALT, demonstrated MTBF, etc.).

Wojciech Jesionkowski

Wojciech leads the development team and strives to bring customers’ ideas to life. During his 14 years at VECTOR as an engineer, he has gained strong problem-solving skills and analytical thinking in product development. Privately, he's a father who loves to spend time with his family on shared outdoor activities and travels.