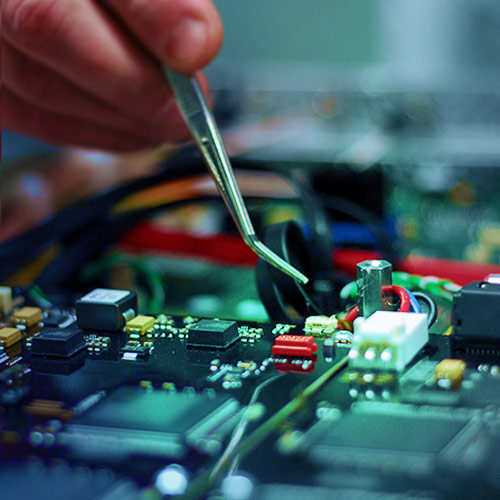

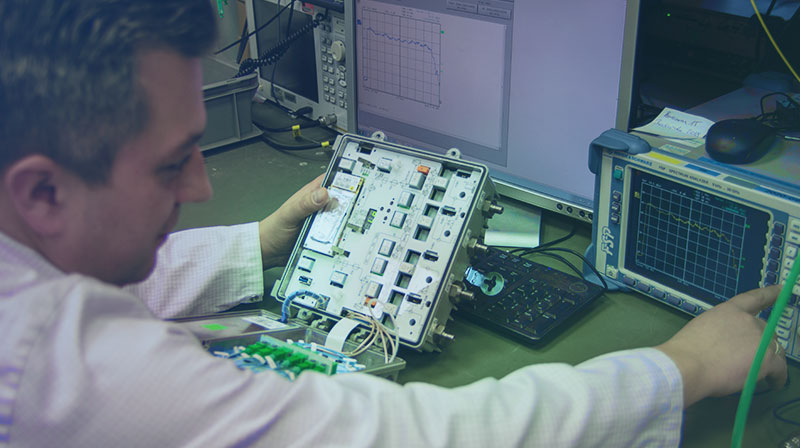

Electronics Prototyping

New Product Introduction (NPI) is one of the most vital processes in electronic product development. Once you start a product development process and then move to New Product Introduction (NPI) process to transform your initial idea into tangible proof, you have to manage various tasks in parallel. To achieve this effectively, you need a nimble and experienced partner who can unlock a repeatable ecosystem where you get to create, test, and optimize your new products while enabling continued scalability of your business.

With our proven methodology in the new product introduction (NPI) process and a team of skilled professionals, your product begins its life cycle at peak reliability and minimum cost, with the most appropriate validation and test procedures.

We can provide you with the ideal transition from design, development, and prototyping to initial production runs, a thorough review of process performance and an evaluation of the new electronic product before implementation. The detailed processes we conduct to ensure that the product is fit for the market include: Design For Manufacturing and Assembly (DFMA), Design For Testability (DFT) analysis, Failure Mode Effect Analysis (FMEA) for risk evaluation, and certification support.