You are safe to focus on your business. We take care of everything else in the design and development process.

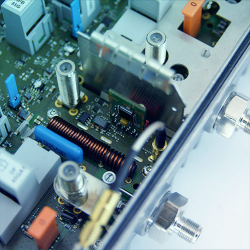

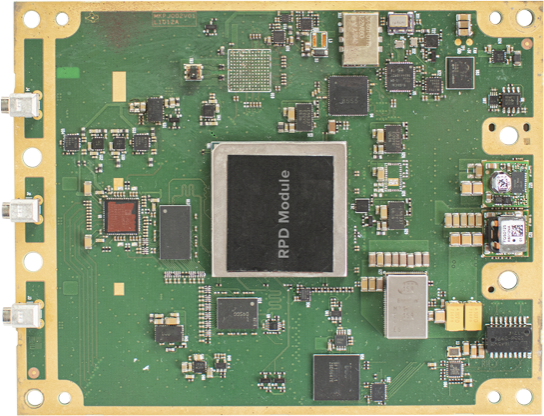

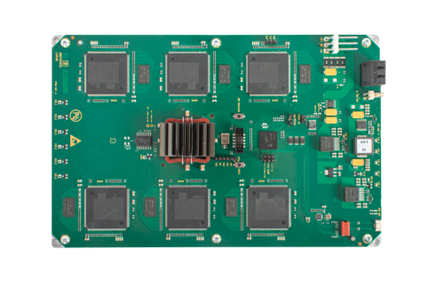

Designing electronic devices on behalf of third parties, both large and medium-sized, has been one of our core activities for a long time. For over 30 years, we have supported our customers in design and development through the design and manufacture of electronic products. Thousands of big data devices include an electronic product design and PCB layout created by our industrial designers.

And as always, we are here for you – a group of designers and printed circuit board assembly (PCBA) engineers who can take care of your electronic product design and development.

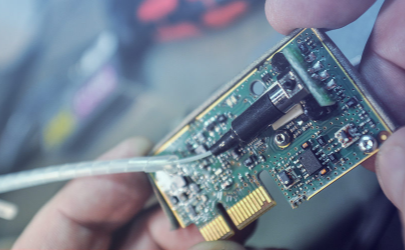

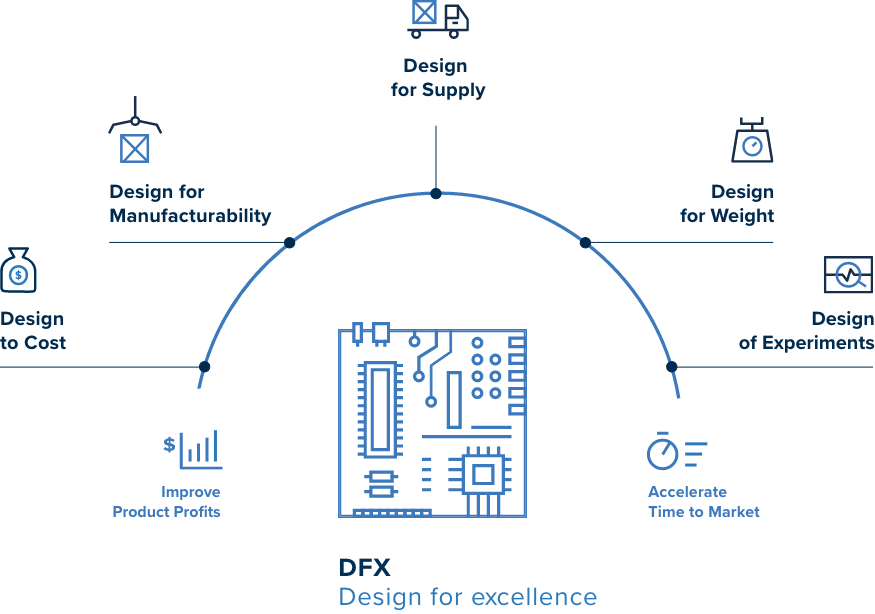

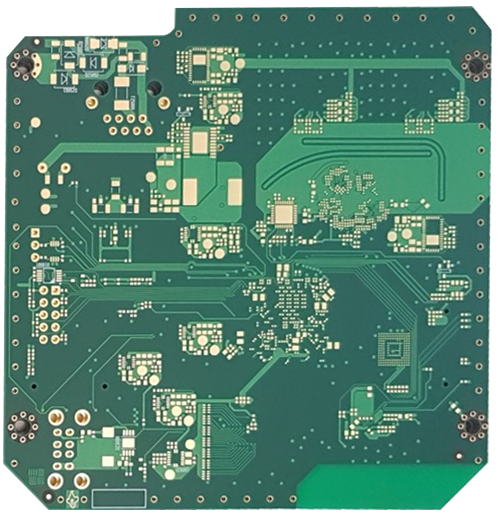

We provide you with expert services in the entire process of designing different types of PCBs: analogue and digital, single- and multilayer. With all of our knowledge and experience, we apply our craftsmanship to bring your product idea to life.

Familiarise yourself with the scope of our electronic product design and development

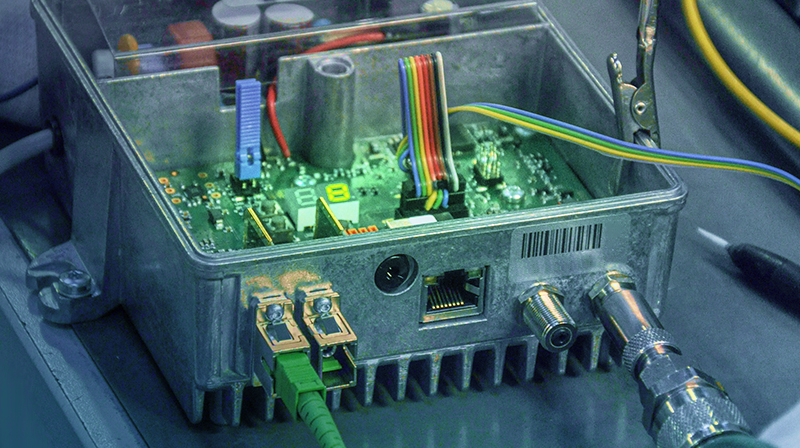

Every electronic product consists of three elements: mechanics, hardware design, and embedded software, which is responsible for communication with other systems. Combining these three elements into one smoothly running electronic device is a significant challenge requiring vast knowledge and broad experience.

MechanicsDesign

HardwareDesign

EmbeddedSoftware Design

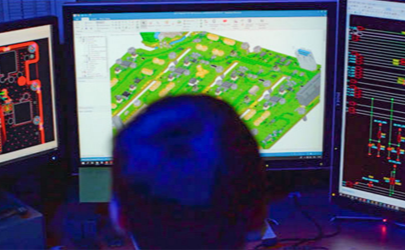

Simulations

Mechanics Design

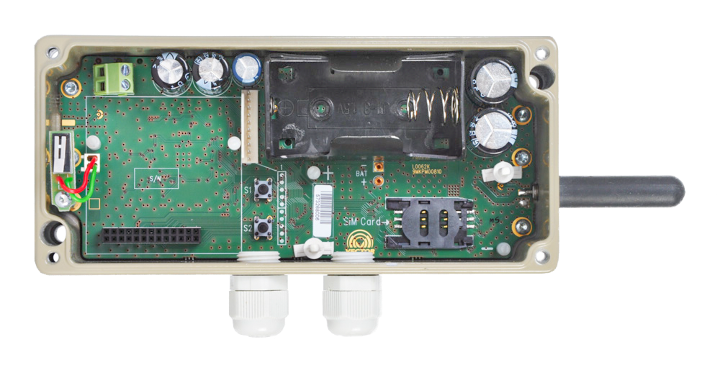

When we design electronic products that end-users will use, we have to meet a range of needs spanning the entire design process to prepare electronic prototypes for manufacturing. In such cases, the mechanics’ design must consider functional expectations and the general aesthetics of the product.

VECTOR BLUE HUB specialises in designing elements with different metals and plastics chosen based on project assumptions and the customer’s requirements. With a rich ecosystem of local vendors and manufacturers of mechanical components and our own CNC centre, we can quickly verify mechanical projects by preparing electronic prototypes.

We understand that prototyping can be expensive, so in certain cases we suggest performing simulations instead. This can be a thermal simulation, EMC radiation or 3D modelling.

Mechanics Design Capabilities:

- Chassis and enclosure design

- Plastic technologies (i.e. Injection moulding, Thermoforming)

- Metal technologies (i.e. Extrusion, die casting, punching & bending, laser cutting)

- CNC milling (In-house machines for quick-turn prototyping)

- Hardened design (IPXX)

- Modelling: Mechanical 3D modelling, Thermal modelling