Prototyping Stage: The First Step in the Design Cycle

At VECTOR BLUE HUB, we take pride in our in-house expertise in providing state-of-art and dependable electronics manufacturing and electronic prototype design services. We know the challenges of prototyping, and our mission is to offer solutions that reduce production time, optimize budget, and improve the efficiency of electronic products.

Prototypes are a vital part of the process of creating, building, and manufacturing an electronic product. Without utilizing a prototype, the process would suffer frequent setbacks that will consume the funds needed for the project.

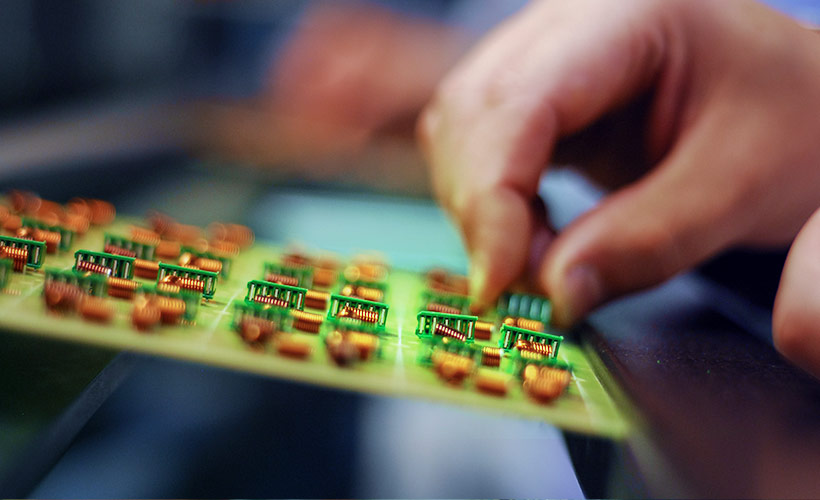

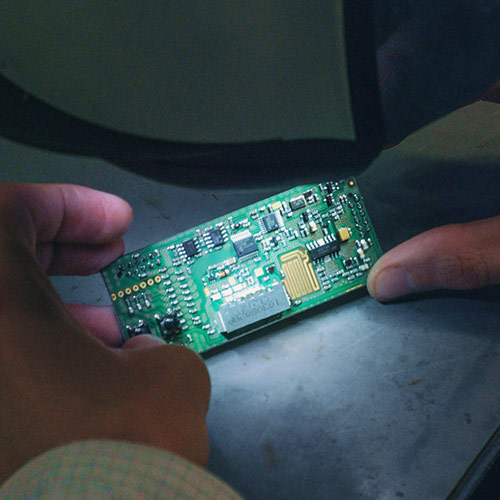

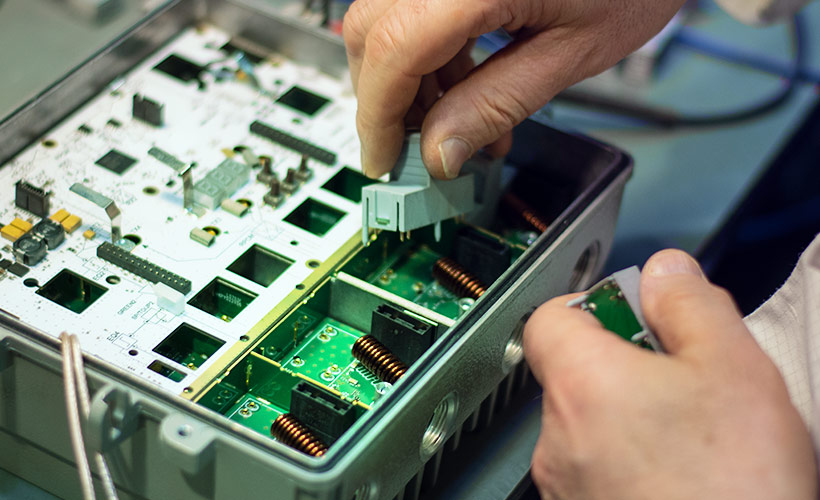

Electronics Prototyping involves a combination of hardware and software designs with PCBs assembled into a functional prototype. Electronic prototypes apply high-tech product techniques, including programming, circuit design, soldering, and wiring. It entails creating circuits with designs, including a breadboard, stripboard, or perf-board. Prototyping boards have holes that will help you to build your electronic components and affix them, the components can be attached through soldering and will depend on the type of board.

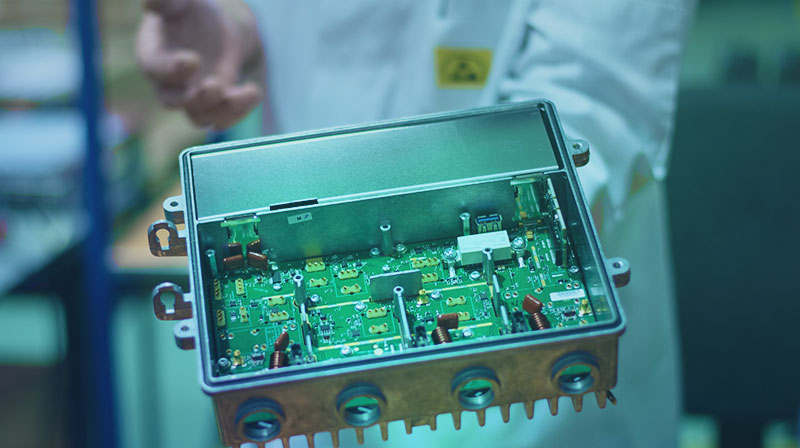

The stages of prototyping include PCB prototyping and product prototyping. In PCB prototyping, we focus on the electronics part of the product, while product prototyping concentrates on the product's functionality.

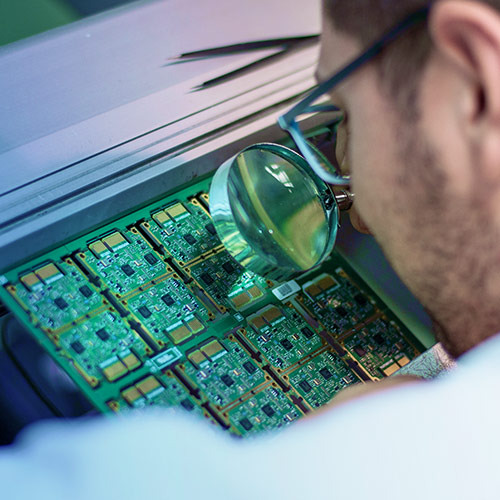

In the prototyping stage, it is possible to check the efficacy of work done by product design engineers. It is a chance to validate the device against the simplicity of installation in the production process and optimization of components and materials involved. It is also the time for a visual assessment of the product's aesthetics and ergonomics.