Electronics Design Services

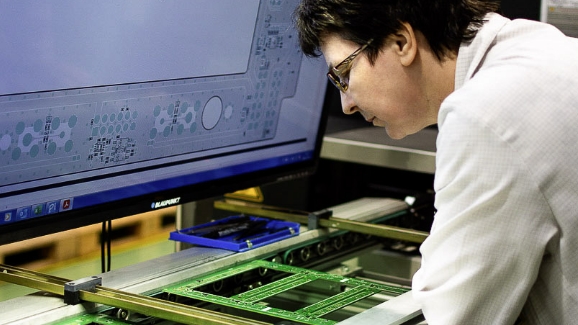

Electronics

Design

Experience in mechanics, electronics and software design - we have it all. We use the freshest design tools and methodologies in our design process to maintain the quality of our design services on the highest level.

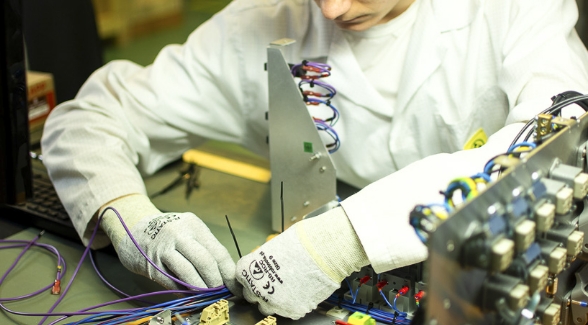

Prototyping

Our prototyping capabilities include: Printed Circuit Board Assemblies (PCBA), 3D Printing, mechanical rapid prototyping, assembly and tests.

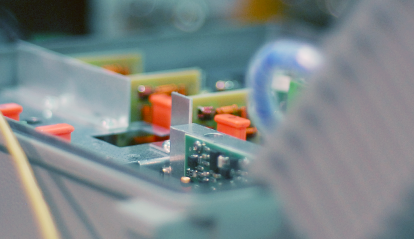

Tests

& Validation

We have a vast experience in carrying out electrical, optical, burning, spurs and distortion, and environmental stress tests. At customer request, we can design any test environment to examine whether the product works as expected.

Product

Certification

We offer worldwide certification, qualification & regulatory services. We can carry out in-house preliminary tests and external tests, and the approval in worldwide recognized laboratories.

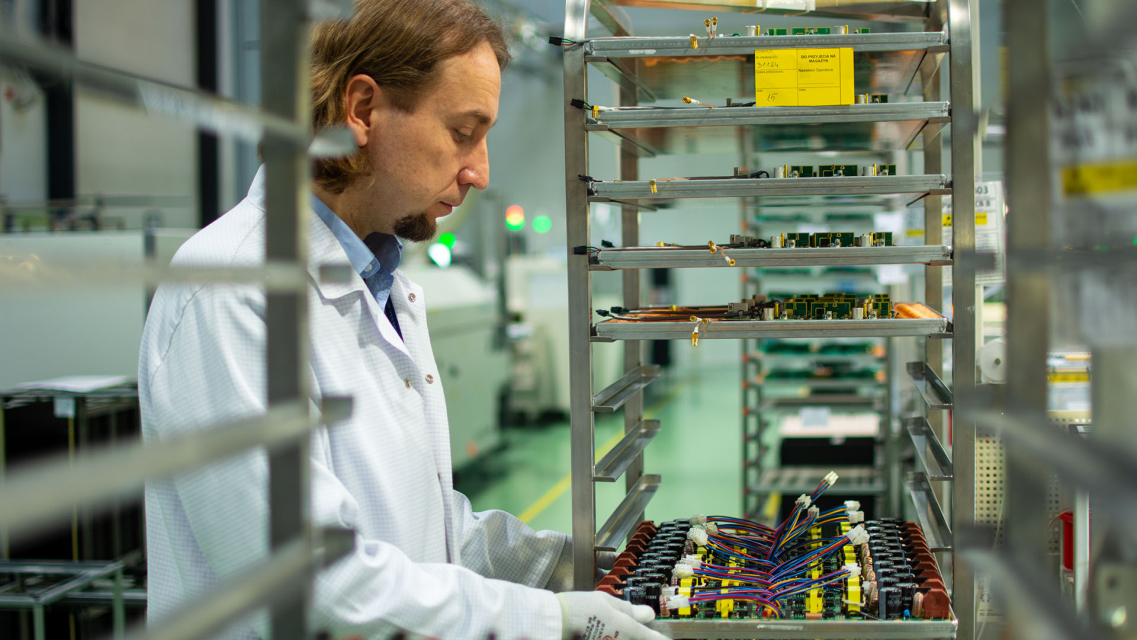

Electronics Manufacturing Services

Contract

Manufacturing

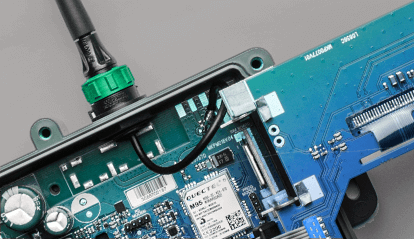

Our contract manufacturing services include surface-mount technology - SMT, through-hole technology THT, final assembly and box build as well as high-mix low-volume production.

New Product

Introduction (NPI)

In our New Product Introduction (NPI) process we rely, among others, on DFMA - Design for Manufacturing and Assembly methodology, FMEA - Failure Mode Effect Analysis and DFT - Design for Testability Analysis.

Sourcing & Supply Chain

Management

We apply material management throughout the product’s life cycle: from solution design, through optimization in cost reduction designs. We also ensure obsolescence management and material availability management.

Engineering Services

& Product Management

Independent teams of engineers are involved in the product life cycle management: from design to manufacture and assembly stage, through alternative materials, and last - time management to product End-of-life.

We are easy to do business with

We represent the Under One Roof concept, keeping the design and manufacturing services in one place to accelerate the time to market (TTM) for your electronic product.

We follow several simple rules every day to ensure the highest level of customer experience.

We invest your money wisely by focusing on the total cost of ownership (TCO), rather than just the price. We value transparency and an open book approach.

With our solid experience in hardware, software and mechanical design, as well as thousands of finished PCBA projects, we treat your product with the same level of commitment and sense of ownership as if it was our own. You are safe to focus on your core business, while our team takes care of everything else.

Watch the short video about our electronic manufacturing services! Play Video

Watch the short video about our electronic manufacturing services! Play Video Areas in which we excel

The know-how we have gathered over the years in leading large-scale, comprehensive projects helps us adjust our electronic design and contract manufacturing services to your business challenges in various industries.

Telecommunications

Industrial IoT

Communication technologies

Smart metering

Electromechanical

A place for your industry

If you haven't found the right area for you, contact us! We will eagerly take a deep dive into a new challenge or serve you with consultancy.

VECTOR BLUE HUB facts & figures

With hundreds of professionals on board and a manufacturing plant based in Poland, we act as your close partner in electronics design and manufacturing services.

35

Years of

experience

+150

Team of

professionals

+90 000

Devices produced

per year

3

Support

departments *

15

[M €]VECTOR BLUE HUB

revenue

60

[M €]VECTOR GROUP

revenue

2000

[m2]ESD surface

protection

1000

[m2]Warehouse

* Product Engineering | Production Process Engineering | Quality Assurance

Hot topics from our knowledge zone

Stay in the loop with some fine exciting content and get the best tips for your business.

C-MAC and VECTOR BLUE HUB Announce Strategic Partnership

C-MAC Electronic Solutions and VECTOR BLUE HUB are delighted to announce a strategic partnership designed to redefine Electronic Manufacturing Services (EMS) with advanced global capabilities and expertise.

Electrostatic discharge (ESD) meaning in manufacturing

Producing and assembling printed circuit boards (PCBs) and other electronic components demands an environment meticulously safeguarded against electrostatic discharges (ESD). ESD, an invisible yet pervasive threat, can compromise the integrity of sensitive electronic components, leading to product failures an...

Understanding the Adaptive Supply Chain

The COVID-19 pandemic accentuated the fragility of the global supply chain, forcing businesses worldwide to co...

A Beginner's Guide: How to choose a PCB assembly company

Choosing the suitable PCB assembly manufacturer is not easy - it's like finding the perfect recipe for your fa...

Exploring comprehensive Electronics Manufacturing Service options: The benefits of keeping your choices open

Bringing together design and manufacturing under one roof marks a big leap forward in turning ideas into real...

How to manage the health of the battery pack - BMS solutions

In an era dominated by technology, where sustainability and efficiency are paramount, battery condition manage...

Where we are

distance from

the Gdansk Airport

15 km

9,3 midistance from

the Gdynia Port

16 km

9,9 mi

Ready to take

THE NEXT STEP?

Leave us your contact info, and we'll make sure to reach out within one business day. Get ready to unlock exciting opportunities!