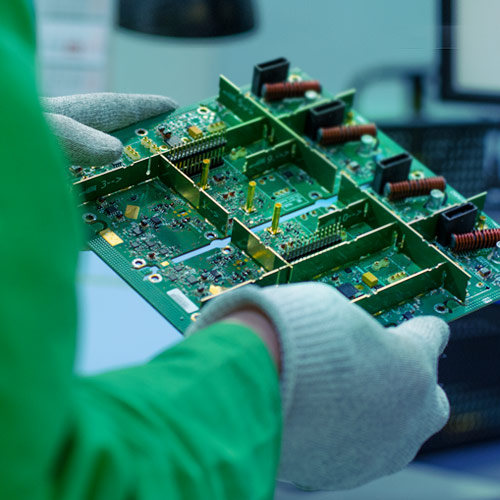

A wide range of Contract Electronics Manufacturing Services

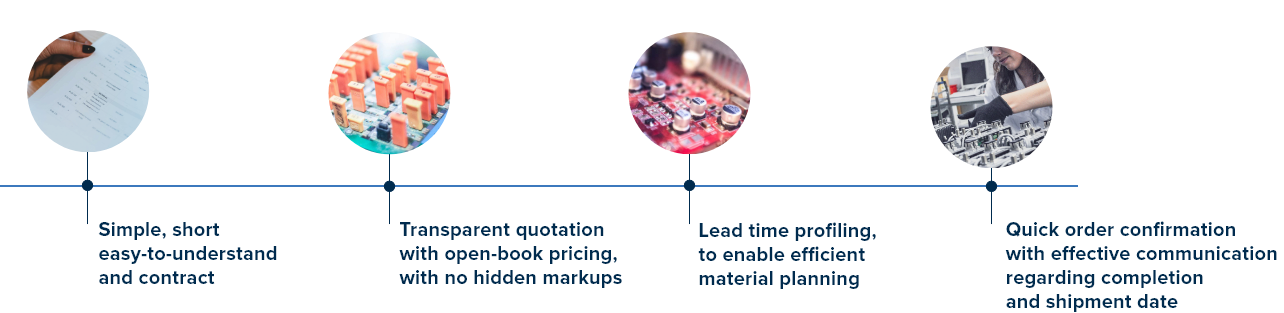

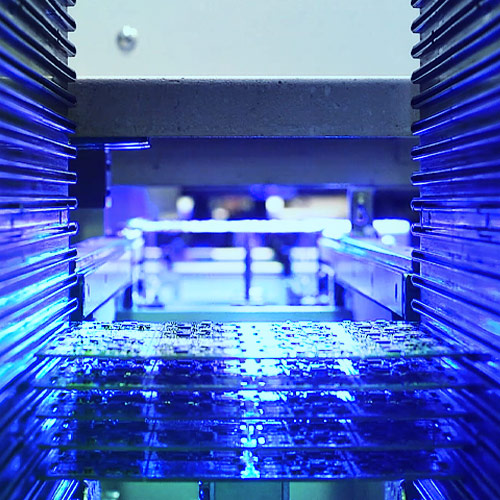

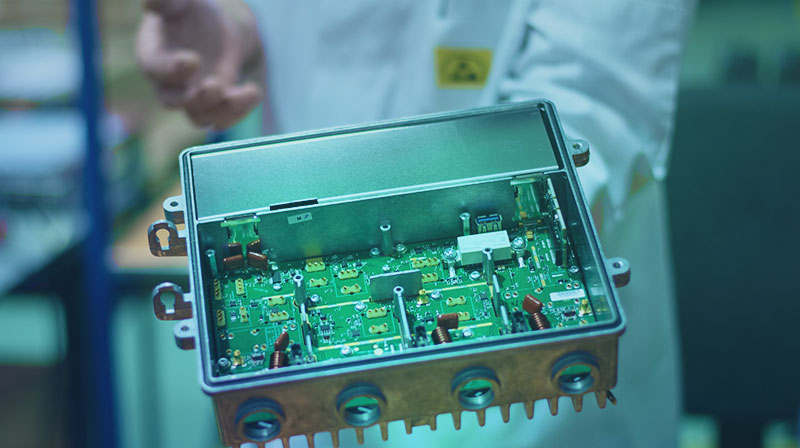

Electronic contract manufacturing can be a complementary or substitute solution to in-house manufacturing operations. VECTOR BLUE HUB is a contract electronics manufacturing company that goes beyond a traditional “build to print” scope. Our ems contract manufacturing services will help you grow your business.

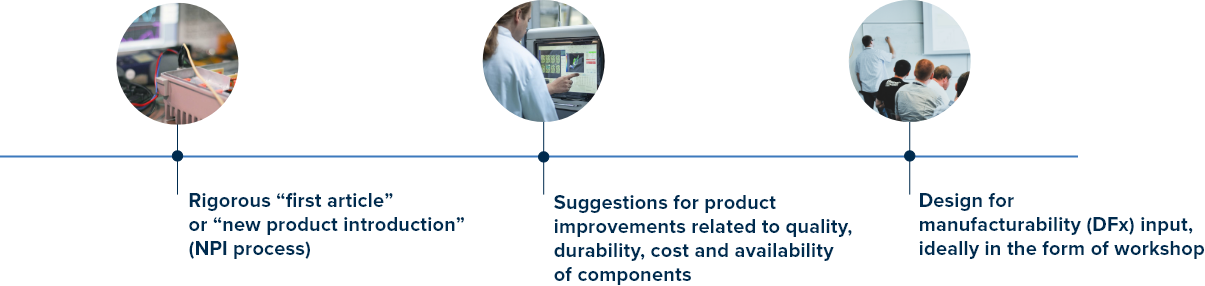

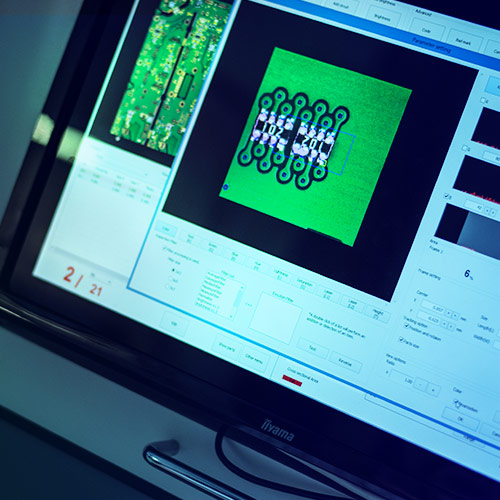

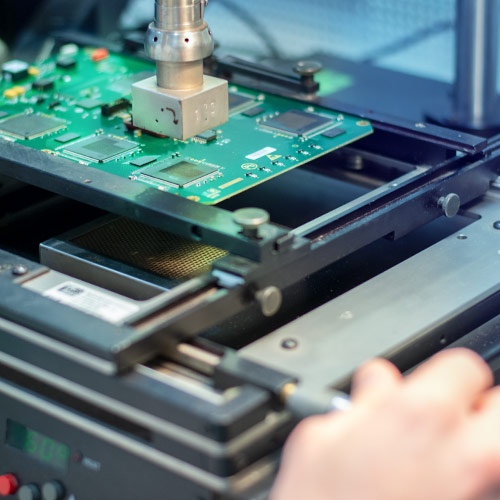

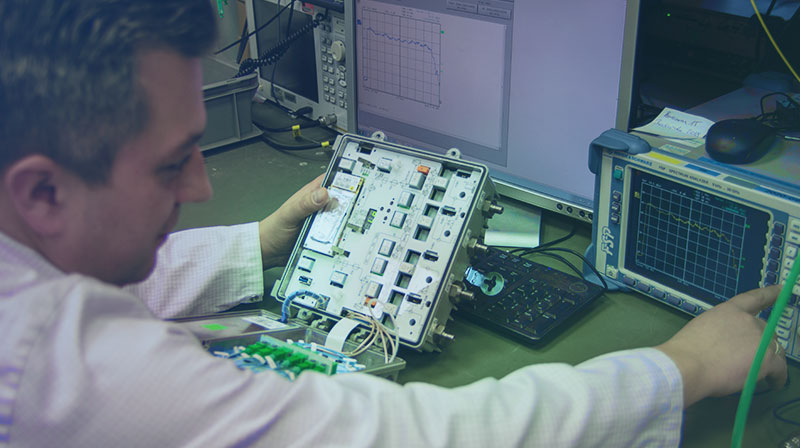

Our preferred customer is the one who wants more from electronics manufacturing services - from co-designing a product, through prototyping and industrialisation, supply-chain planning towards after-sales services such as reverse logistics, repair, electronic products sustaining, quality control, and lifecycle management.

We believe in integrating services and providing a one-stop-shop full range of electronic contract services required in a product's lifecycle. We offer comprehensive electronics contract manufacturing services regardless of what customers need to launch new products or upgrade older models to meet rising market expectations.

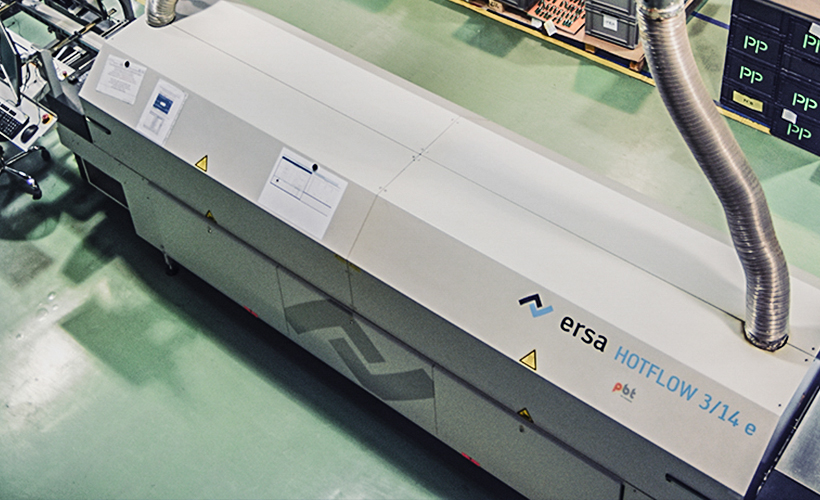

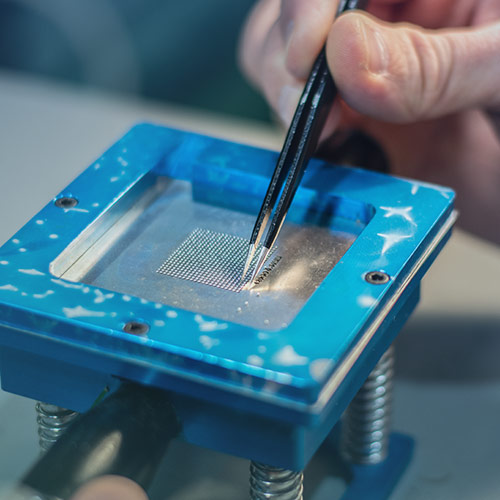

Our flexible production process management, flexible factory layout, and extensive product line retooling capabilities allow us to meet non-standard needs, making us the best among other contract electronics manufacturers.