Quality management in electronic devices industry

Project in electronic devices industry, if successful, comes from what the client wants and what the market expects. Between them springs up quality – the bridge between a company and its clients. Quality planning is then answering the question how to deliver what is in demand. But why does it take so much to plan this very process, especially in manufacturing electronic devices, and when to call quality enough?

Quality in manufacturing electronic devices

entails many departments and people to be planned. Especially when it is

outsourced. As one of the fastest growing trends in the electronics industry, it

looks day by day more attractive to many businesses which now more often contract

their production outside to cut the costs down or reduce time to launch the

product on the market. From the first scratch to the assembled device a lot

might change – compatible technology, demand or politics. No matter the change,

all comes down to not overpaying for the production. This is why you should

plan the quality of a product.

And there are many issues that can make the

plan veer unexpectedly:

Undue output – producing too much, or even not enough, is a

real threat in case of the changing market demands.

Lack of information – fast tempo, multi-tasking or information

clog leads to missing what is going on in the project.

Unbalanced workload – keeping quality on a desired level needs

properly distributed people among their work stations to maintain the work

flowing the right pace.

Incompatible manufacturing speed – magazine stock, assembly stations

and tests – they all need smooth and easy progress.

Non-compliant product – such an outcome is the result of

an unorganized quality control management and that, speaking of control, is a real control light

for the whole process.

Not too cold not too hot –

quality management

Non-compliant product is realistically the

worst scenario that can happen to any outsourcer. Too broad and general

guidelines will more than sure mislead the team to create a product of unwanted

features. Saying: “It must be good,” says, in truth, nothing.

Giving too general guidelines and trying for

the product to be the best of the bests is a risky business. Adopting an unclear or short product design

specification can result in the launch of an unwanted product on the market,

and, of course, the loss of a lot of money. On the other hand, exhaustive specification

guidelines may clog somewhere in the gorge of the company’s operational

tactics. After many days spent on mastering only one feature, it all may come

up as unnecessary, while it only needed to be better supervised by a quality control manager, who sees the process as a whole and knows where to switch the

track.

“A proper plan opens the gate to potential

marketing the product. In VECTOR BLUE HUB we work closely with clients at every

stage of the project to understand their needs and finally give them the

optimal solution,”

says Piotr Krauze, Quality & Reliability Assurance Director.

The market is changing and it is essential to optimize

the product by ongoing working on its vitality.

“We simply answer the question if anyone still

needs this particular product with these particular specifications?” Piotr

points out.

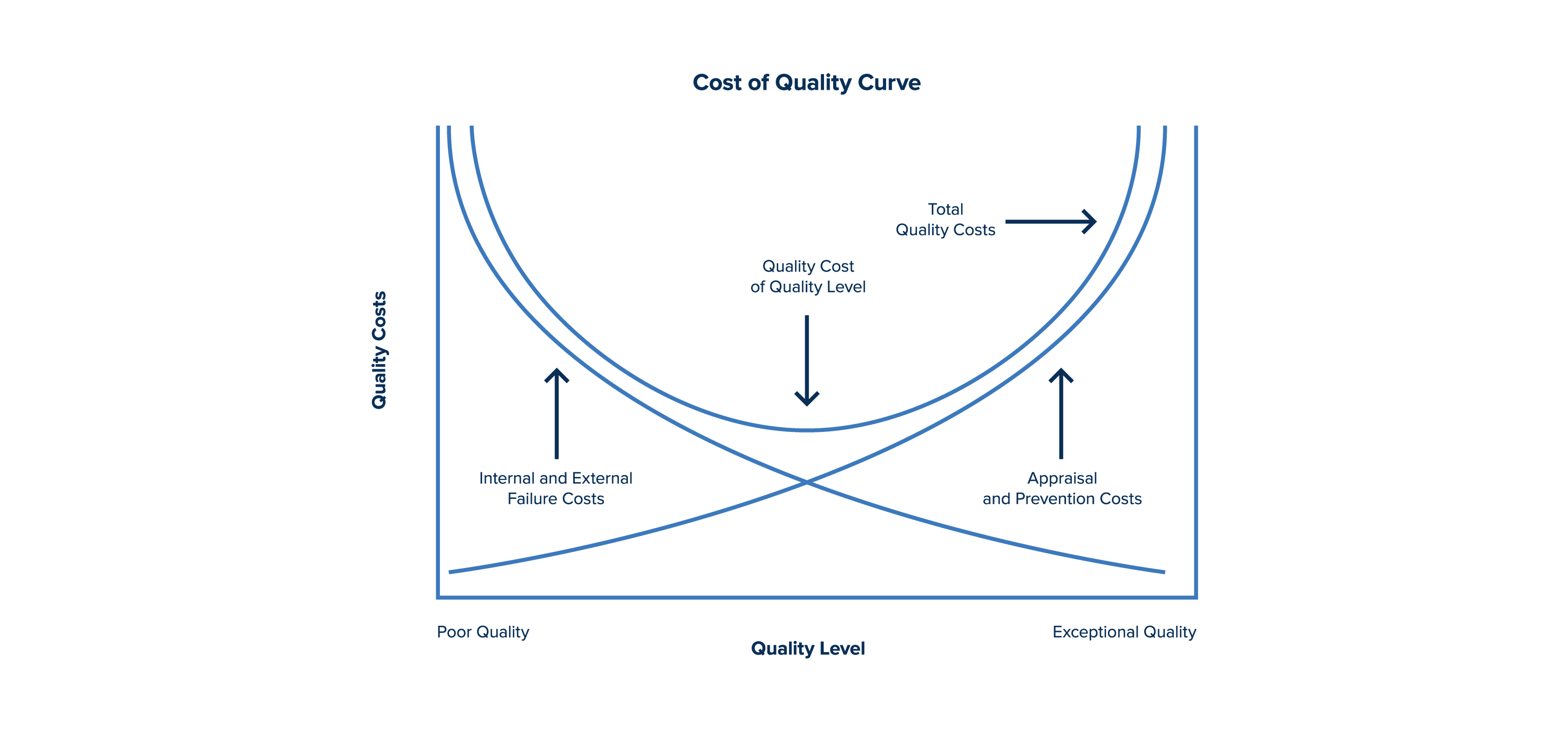

Investing in quality reduces

time

Having both design and manufacturing divisions

on board entails quality management as mandatory. The later the stage of

quality control is introduced to the project, the more costs weigh down the end

product, and that results in not delivering the end value. Too little attention

paid to quality increases the risk of later service costs, complaints or even

loss in the future business opportunities. Too much scrutiny, however,

decreases maintenance costs but increases the entry level, namely, the price.

The whole game swings around the point in the middle – to deliver satisfactory

product quality together with low costs of investment and maintenance.

Keeping quality on track

Quality assurance in development and

manufacturing electronic devices is not a static, once settled decision. To

keep it going the right track there come invaluable tools which, when planned

and rightly implemented, make the quality process smooth. The range of such

tools reflects best what quality management really is – it is a touchpoint of a

company and the market. Quality sees the company from the helicopter view and

it goes across the divisions and departments to assure that all the resources

contribute to sustaining what the clients expect.

Tools of quality management:

Process. That reflects the broadest scope of all

tools. It incorporates continuous improvement, ongoing optimization and adjusting

the product to the market. A well-planned process answer to the problems

concerning risk management. Components short supplies, market niche satiation

or shorts in the workload – they all needed to be named as the risky points.

After the process is planned, there comes the moment for the next tool.

People. They are not only engineers responsible for

technical improvement and development, but also managers who keep eye on

whether tasks stay open or fall into the done category.

Traceability system. It track components, manufacturing

itself, gather data in real time and does everything to reduce human error. It

is constituted by the laboratory, thorough documentation and IT softwares for

work organization.

Certification. These documents are the best proof that

a company has acquired some requirements which will guarantee repeatability of

product quality. A certificate says that someone from outside the company has

accredited the way the job is done.

Quality management in huge part is about

overall managing the project. That is why it takes so much so many people into

organizing it. Planning, let us say it, prevents unpredicted spendings, even if

at the beginning it calls for some. The answer when to say enough to quality

development is at the moment when the market need is covered with a

well-managed product. The wanted and bought outcome is the best proof for the

best quality. Quality is nothing more, thus, than a language between the end

user and the producer, as it allows them to fulfill their needs.