Why to produce electronics in Europe?

After a few years of European electronics manufacturing services (EMS) market stagnation there has come the time for the rebirth. The European EMS industry will have reached 32 billion euro by 2021 as the Reed Electronics Research's report says. ADAMCIT (Aerospace & Defense, Automotive, Medical, Control & Industrial and Telecom) sectors in this area will soon be getting bigger and bigger at a compound annual rate of 2.8% on average. Those promising numbers reveal the answers to the questions like: “Why to produce electronic devices and components in Europe?” And the fact that more companies follow those on the winning streak does not provide any answer.

But before going to the bullet points of the matter, there should be a clear outline of the reason why the market of Electronic Manufacturing Services grows. The situation pictures itself so mainly because the price pressure overwhelms what happens in the western part of the world – Western Europe included. Original Electronics Manufacturers (OEM) wait for local manufacturing companies to offer their services for many reasons. One of them, and probably the most driving one, is market testing. There are a few ways of solving the problem of scarcity of time needed for marketing products and having an EMS company right behind the corner opens the most important doors – the one that allows to be the quickest.

Rapid prototyping

In today’s fast world of changes, being the first does not count anymore as valuable. A company might be the first for a limited span — weeks, months — before the competition outpaces the race. The factors that add up to firstness come in many, however, rapid prototyping allows as one of not so many for shaping and reshaping your product according to the market demands on the fly.

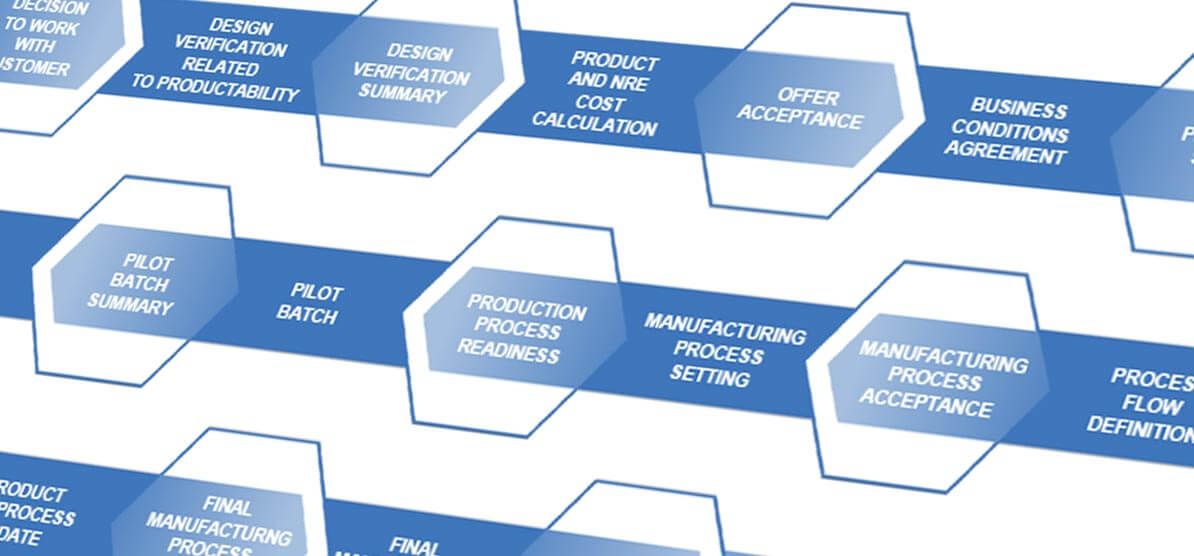

A local manufacturer keeps the process close to the client, e.g. launching a pilot batch or settling down the production readiness — they both call for short logistic realization. Depending on the natural conditions and market environment a prototype is the key to the new product introduction when the launcher researches the client and where the product is going to be working.

Operations, which prepare a device for such a test, traverse design and manufacturing processes. For the products that are to be launched on the European market, thus, it is vital to react quickly to the upcoming changes.

Closeness

Although the key sectors like: consumer, computing and communication are going to be focused of the higher volumes, thus, sent to the asian manufacturing titans, new product introduction might need to delegate a product owner. Such a person plays the elementary part in the process as a bridge between the producer and the company. Planning production process, on-site verification, visit in the manufacturer's factory - those loom over many product launches, where the product owner and the company's other delegates are more than welcome to participate in. An over-a-day flight does not facilitate the mission.

Insignificant as the case may seem, every operational manager will appreciate agility with which the meetings can be organized with. It is time and cost-saving, reduces the risk of launching a non-compliant product due to accessibility of project development and leaves a possibility to engage local partners like: material providers, universities and government.

Partners play an essential role in keeping the supply chain reliable. Especially in such industries like: military, health, insurance or ecology, plethora of overwhelming certificates or terms to be met come in the way of producing anything. What is curious, it is not even about the risk of material quality, but measurement of risks which may increase the total cost of ownership. Surprisingly, cultural differences, language barrier or unwelcoming law only add to the time of making a new and unknown supplier a trusted partner. Along with trust escalation, there come innovativeness, customization, flexibility and leanness in supply chain management, which together in the total cost of ownership may efficiently reduce the company's loss.

Costs

What does not come as the first idea, with small and medium volumes the cost might be well-reduced when components or whole devices are produced in Europe. Logistics. Who would be surprised by the fact that a month-travel of our electronics through the seas amounts to higher spending per piece than we manage the same by a night drive on a truck?

Besides, the whole quality management system operates on the client's perspective. It does have to be someone who steps with one foot on the market side and with the other on the engineering one. The quality team is to optimize the production costs through an accurate evaluation of the market demands and production possibilities — including the factory itself and the whole spectrum of the environment (people, politics, law, technology development, etc.) which influence using the product. Quality management works closely with the product's environment, thus, and takes care that the product functionalities meet what is expected — not too much, not too little.

Will it last forever?

The competitiveness fueled by the OEMs searching for the more efficient producers which will provide them with quick and cheap services temper some of the European manufacturers. Although consumption in Europe grows (semiconductors, passive or electromechanical components) the situation on the market is unstable. The position of infamous China is changing to the most famous one. That changes the distribution of market forces for a more dispersed picture of manufacturers worldwide.

In times of instability, finding a trusted business partner appears even more important. Making the supply chain as efficient as it can be called for connections and partnership. These things come at a price… with definitely a proper return on investment.